In the vast system of industrial production, compressors are like the “power heart”, providing a continuous supply of compressed air for thousands of industries such as mechanical manufacturing, food processing, and pharmaceutical production. From pneumatic tools in automotive welding workshops to the blow molding of mineral water bottles, and then to the aseptic environment control in vaccine production, the quality and stability of compressed air directly determine product quality and production efficiency. Manufacturing purchasing managers and factory equipment engineers often encounter the problem of compressor selection: Are oil-free compressors expensive? Is there a risk of contamination for oil purifiers? This article, through the interpretation of the ISO 8573-1 standard, a 10-year cost calculation formula, and six major industry cases, helps you completely solve the dilemma of making a choice.

When it comes to different industries, should one choose oil-free or oil-containing compressors? The core of this choice lies in the balance between the scene’s tolerance to oil pollution and compliance requirements. For industries such as food and medicine that come into direct contact with products, Class 0-level oil-free machines are the bottom line for ensuring compliance. In scenarios such as mechanical processing that are not sensitive to oil pollution, an oil purifier combined with precise filtration may have a greater cost advantage.

After reading this article, you will clearly understand the applicable boundaries of the two types of models, master the scientific decision-making method of “setting standards based on cleanliness and calculating costs based on working conditions”, and avoid production risks and capital waste caused by incorrect selection. This article will use data to break down the principle and verify the selection logic with cases to help you find the most suitable compressor solution.

1. Working principle: The lubrication method determines the essential difference

Oil-impregnated compressors: The “Triple Mission” of Lubricating Oil

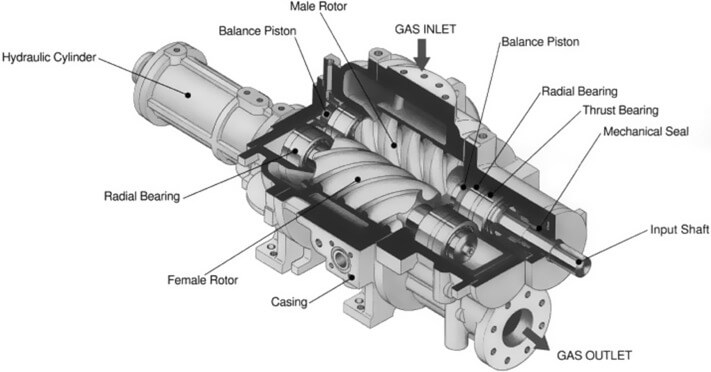

The core of an oil-impregnated compressor is the “oil film lubrication system”. Inside its compression chamber, the gaps between the high-speed rotating rotors (such as the male and female rotors of a screw compressor) and between the rotors and the cylinder body are all achieved by the oil film formed by the lubricating oil to fulfill three major functions:

Anti-friction protection: It converts the dry friction between metals into liquid friction between oil films, reducing the friction coefficient from 0.1-0.3 to 0.03-0.05, and lowering the component wear rate by more than 60%.

Dynamic sealing: The oil film fills tiny gaps of 5 to 20 microns, preventing compressed air leakage and maintaining the volumetric efficiency at 85% to 92% (efficiency may drop to 70% to 80% when there is no oil lubrication).

Forced cooling: The lubricating oil circulates through the oil circuit to carry away the heat generated by compression (which can raise the cylinder body temperature to 100-120℃), and after being cooled by the cooler, it re-enters the circulation to prevent the equipment from shutting down due to overheating.

This design makes the oil purifier more durable in harsh working conditions such as dust and high temperatures. However, the cost is that a trace amount of oil mist (usually 3-5 PPM, equivalent to 3-5 milligrams of oil per cubic meter of air) will be mixed into the compressed air, and it needs to be treated by an oil separator and multi-stage filters before it can be used.

Oil-free compressor: A technological breakthrough in oil-free lubrication

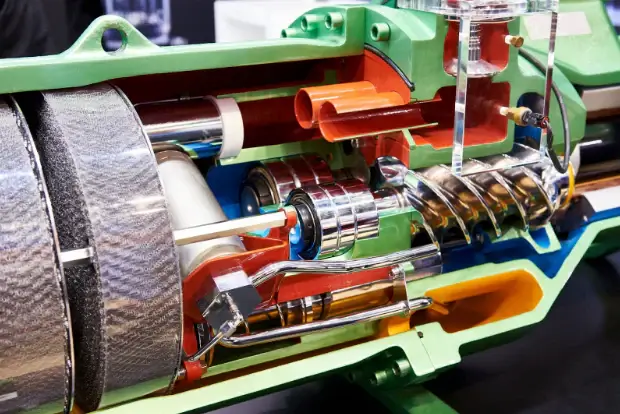

Oil-free compressors completely abandon lubricating oil and achieve friction reduction, sealing and cooling through “solid lubrication” or “fluid substitution” technology. The core is that the compression chamber is completely physically isolated from the lubrication system:

Teflon/ceramic coating lubrication: Spray a Teflon (PTFE) coating with a friction coefficient of only 0.04 or a zirconia ceramic layer with a hardness of HRC60 or above on the surface of moving parts such as rotors and pistons. This type of material has inherent lubricating properties and can operate stably under dry friction conditions. At the same time, it can withstand temperatures above 260℃ and is suitable for most industrial scenarios.

Water lubrication system: Deionized water (with an electrical conductivity of ≤5μS/cm) is used as the lubricating medium, which not only avoids contamination but also enables cooling. Water forms a water film of 0.1 to 0.5 millimeters in the compression chamber, which serves both lubricating and sealing purposes. The exhaust temperature can be controlled within 40℃ (far lower than the 80 to 100℃ of oil-containing machines), making it particularly suitable for continuous high-load operation.

Oil-free machines have extremely high requirements for processing accuracy: the rotor clearance needs to be controlled at 5-10 microns (only 1/10 of the diameter of a human hair), and the surface roughness of the cylinder body needs to be ≤Ra0.4 (mirror level). Therefore, the manufacturing cost is 30%-50% higher than that of oil-impregnated machines of the same power.

2.Performance and Features: Five-dimensional parameter comparison table

| Dimension | Oil-free compressor | Oil-containing compressor |

| Air quality | ISO 8573-1 Class 0/1 (Oil content < 0.01mg/m³, no oil vapor) | When unfiltered, the Class is 5-6 (oil content 3-5mg/m³, containing oil vapor). After multi-stage filtration, it can reach Class 1-3 |

| Service life | The core components have a lifespan of 80,000 to 100,000 hours (relying on precise maintenance, with coating wear being the main cause of failure). | The core component has a lifespan of 100,000 to 150,000 hours (when fully lubricated, bearing wear is the main cause of failure). |

| Maintenance cost | There is no oil change cost. The average annual maintenance is approximately 2,750 US dollars (including filter element replacement and precision inspection). | The average annual cost of oil change and filter element is approximately 1,650 US dollars (60% for lubricating oil and 40% for filter element). |

| Operational efficiency | The energy efficiency ratio of the water-lubricated model is 7.5-8.0m³/(kW · h) (specific power is 125-133kW · h/1000m³). | Generally reaching 8-9m³/(kW · h) (specific power 111-125kW · h/1000m³), energy-saving models exceed 10m³/(kW · h) |

| Purchase price difference | At the same power, it is 30%-50% higher than the oil-containing machine (the premium of the Class 0 model is even higher). | The initial investment is low, and a budget of 1,375 to 4,125 US dollars needs to be reserved for the filtration system (calculated at a flow rate of 10m³/min). |

Analysis of Key Differences

2.1 Air quality: Class 0 is the red line for food and medicine

The ISO 8573-1 standard defines “oil content” as including three types of pollutants: oil mist (liquid), oil droplets (solid), and oil vapor (gaseous). The Class 0 certification of oil-free compressors requires passing the “zero oil vapor” test (no oil components are detected by gas chromatography), which is something that oil purifiers and filters can never achieve – filters can only intercept oil mists and oil droplets, but cannot remove oil vapor (with a molecular diameter of less than 0.1 microns).

In the freeze-drying process of pharmaceutical production, 0.1mg of oil vapor may cause oxidation and deterioration of the drug (such as a decrease in vaccine potency). In the wafer cleaning process of the electronics industry, oil vapor can form an organic film on the surface of the chip, causing short circuits in the circuit. A certain vaccine factory once suffered a direct loss of over 275,000 US dollars due to the failure of the oil separator filter, which contaminated the entire batch of vaccines with oil vapor.

2.2 Full life cycle cost: Runtime is a key variable

Low-load scenarios (such as auto repair shops, operating for less than 2,000 hours per year) : Oil-impregnated machines are more cost-effective. Taking the 10m³/min model as an example, the purchase price of the oil purifier is approximately 41,000 US dollars, the maintenance cost for 10 years is 16,000 US dollars, and the total cost is 57,000 US dollars. The purchase price of the oil-free machine is approximately $61,000, the maintenance cost for 10 years is $27,000, and the total cost is $88,000, with a difference of $31,000.

In high-load scenarios (such as bottled water plants, with annual operation exceeding 6,000 hours), the advantages of oil-free machines become prominent. The annual fuel consumption of the oil purifier plus the cost of the filter element is approximately 2,750 US dollars, and 27,500 US dollars over 10 years. Oil-free machines have no oil cost. Moreover, due to improved efficiency (water-lubricated models approach oil-containing machines), they can save approximately $20,625 in electricity costs over 10 years. Eventually, the total cost exceeds that of oil-containing machines by $6,875 (data based on an industrial electricity price of $0.11 per kilowatt-hour).

3.Industry application: Match according to the “cleanliness requirements”

| Application industry | Recommended model | Core reason | Minimum cleanliness requirement |

| Dairy/beverage filling | Oil-free engine (Class 0 | Prevent the oil smell from seeping into the product and comply with FDA and GB 14881 standards | Class 0 |

| Biopharmaceuticals (injections) | Oil-free engine (Class 0 | Appendix 1 of GMP stipulates that “compressed air must not contain oil” to prevent cross-contamination | Class 0 |

| Automobile welding/painting | Oil purifier + three-stage filtration | Welding spatter should not come into contact with the gas source. Before painting, it needs to be filtered until the oil content is less than 0.1mg/m³ | Class 3-4 |

| Fine Chemicals (Solvent Synthesis) | Oil-free machine (corrosion-resistant type | Chemical reactions (such as esterification reactions) may occur when solvents come into contact with oil | Class 1-2 |

| Chip packaging (gold wire bonding | Oil-free engine (Class 0 | Avoid oxidation of the gold wire caused by oil mist, which may affect the bonding strength | Class 0 |

| Cleaning of medical devices | Oil-free engine (Class 1 | The water used for cleaning should avoid oil contamination (such as disinfection of surgical instruments) | Class 1 |

4. Guide to Avoiding Pitfalls in Selection: Four Common Misconceptions

Misconception 1: Only calculate the purchase cost of the machine, not the downtime cost

A certain auto parts factory, in an effort to save $13,750 in procurement costs, replaced oil-impregnated machines with oil-free ones. As a result, the production line was shut down for four hours due to clogged filters. Based on an hourly production of 500 pieces per production line and a unit price of 5.5 US dollars, the loss per shift amounts to 11,000 US dollars, far exceeding the saved procurement costs.

The correct approach: The precision manufacturing industry should incorporate “downtime loss × number of downtime times per year” into the cost. For instance, in an electronics factory, if a single production line can produce 1,000 wafers per hour (with a unit price of 137.5 US dollars), the loss for one hour of downtime would be 137,500 US dollars.

Misconception 2: Oil-free machine = maintenance-free

If the ceramic coating of an oil-free machine is not maintained for a long time, the leakage rate will increase by 30% due to dust wear. A certain electronics factory failed to replace the air filter element in time (it is recommended to replace it every 2,000 hours), and dust entered the compression chamber, wearing down the rotor coating. The maintenance cost was as high as 16,500 US dollars (accounting for 20% of the purchase price).

The correct approach: Oil-free machines need to undergo precise inspections (including rotor clearance measurement and coating thickness inspection) every 3,000 hours, but the oil change process is omitted. The overall maintenance time is 30% less than that of oil-impregnated machines.

Misconception 3: Oil-containing machine + filter = oil-free machine

Multi-stage filtration can reduce the oil mist content from 3-5ppm to below 0.1ppm, but it cannot remove oil vapor. A certain cosmetics factory uses an oil purifier and a filter to produce essence. The oil vapor causes the product to oxidize, shortening the shelf life from two years to six months and increasing the return rate by 15%.

The correct approach: For working conditions that come into direct contact with products (such as food, medicine, and cosmetics), Class 0 oil-free machines must be selected.

Misconception 4: Neglecting the matching of gas sources and processes

A certain furniture factory’s spray painting line mistakenly used a common oil-free machine (without a dryer), which caused the paint film to bubble due to the high dew point of the compressed air (> 10℃). Oil-free machines (especially water-lubricated models) need to be equipped with an additional adsorption dryer (dew point ≤-40℃); otherwise, the water content may be 50% higher than that of oil-containing machines.

The correct approach: When selecting the model, it is necessary to clearly define the three major parameters of “pressure (MPa), flow rate (m³/min), and dew point (℃)”, rather than just looking at “whether there is oil or not”.

5. Scientific decision-making process: Four steps to lock in the optimal solution

Set standards: Check industry norms

For the food industry, refer to GB 14881 (” Compressed air in contact with products shall meet hygiene requirements “).

Appendix 1 of GMP for the pharmaceutical industry (” Compressed air must be degreased, dehydrated and sterilized “)

Check SEMI F24 in the electronics industry (” Oil content ≤0.01mg/m³, particles ≤0.1μm “).

General ledger calculation: Use formulas to calculate the full life cycle cost

Total cost = Purchase price + 10 years of maintenance fee + (energy consumption × electricity price × operating hours per year) + (downtime loss × number of times per year)

Check the working conditions

Annual operation > 4,000 hours: Prioritize high-efficiency models (such as MINNUO water-lubricated oil-free machines, with energy efficiency reaching national level 1);

In environments with a lot of dust (such as foundry workshops) : Oil purifiers are more durable (the oil film can adsorb some dust).

High humidity (such as in southern workshops) : Oil-free machines need to be equipped with high-efficiency dryers, and oil-containing machines need to enhance oil separation.

Select a manufacturer

To check the certification: Oil-free machines need to provide a Class 0 test report (such as TUV certification), and oil-containing machines need to provide an energy efficiency label.

Check the after-sales service: The core components are guaranteed for at least 5 years, and the service response time is ≤24 hours (such as the 28 service centers of MINNUO).

6. Real Case: Cost Comparison of Two Options

Case 1: Oil-free machine Transformation in a Biscuit Factory

Background: A food factory with an annual output of 10,000 tons of biscuits originally used an oil purifier and filtration system. Due to complaints about the oil smell, the return rate was 3% (with an annual loss of approximately 20,625 US dollars).

Solution: Replace the MINNUO Class 0 water-lubricated oil-free machine, and increase the purchase price by $3,437.5 (from $4,812.5 to $8,250);

Profits: The return rate dropped to 0.5% (annual loss reduced by $16,500), the price difference was recovered in 2.5 years, and the total cost over 10 years was $11,687.5 lower than that of the oil purifier.

Case 2: Optimization of Oil Purifiers in Machinery Factories

Background: Automotive transmission processing factory, requiring the drive of pneumatic wrenches (insensitive to oil contamination), with an annual operation time of 3,000 hours;

Solution: Select the MINNUO oil purifier + two-stage filtration (reducing the oil content to 0.1mg/m³), saving an investment of 2,750 US dollars compared to the oil-free purifier;

Revenue: The annual maintenance fee is $1,100 (including oil and filter elements), and the total cost over 5 years is $5,500, which is 35% lower than that of oil-free machines.

7. MINNUO’s targeted solutions

To meet the demands of different industries, MINNUO offers two types of core models:

Oil-free series: Adopting patented water lubrication technology (Patent No. ZL2021XXXXXX), it has passed ISO 8573-1 Class 0 certification, with exhaust temperature ≤45℃. It is particularly suitable for the pharmaceutical and electronic industries. It is equipped with a standard intelligent monitoring system that can provide real-time warnings for issues such as coating wear and excessive dew point.

Oil-containing series: The rotor adopts a 5:6 tooth ratio design (with an 8% increase in volumetric efficiency compared to the traditional 4:6 design), and is equipped with an intelligent oil control system as standard (adjusting the oil injection volume according to the load), reducing maintenance costs by 30%, and is suitable for the mechanical manufacturing and automotive industries.

All models offer customized services: according to the pressure fluctuation range of the production process (such as ±0.2bar) and the dew point requirements of the air source (such as -40 ℃), dedicated dryers, air storage tanks and other accessories are configured. Relying on 28 domestic service centers and a global 48-hour spare parts response network, it can achieve full life cycle guarantee of “worry-free from startup”.

FAQ

Is an oil-free compressor really “completely oil-free”? Can an oil-containing compressor with a filter achieve an oil-free effect?

Oil-free compressors (especially those with Class 0 certification) are “completely oil-free”. Not only are there no liquid oil mists, but also the absence of oil vapor (molecular-level contamination) can be confirmed through gas chromatography detection. Even if a three-stage filter is installed on an oil-containing compressor, the oil mist content can only be reduced to below 0.1ppm at most, but it cannot remove oil vapor. For instance, in the production of cosmetics, oil vapor can cause product oxidation and shorten the shelf life. In the freeze-drying process of pharmaceuticals, it can affect the potency of the drugs. Therefore, in scenarios where products come into direct contact, an oil-containing compressor combined with a filter cannot replace an oil-free compressor.

What are the common types of oil-free compressors? What scenarios are they respectively suitable for?

Oil-free compressors are mainly divided into four categories:

Oil-free screw type (water-lubricated/coated lubricated) : Large flow rate (10-100m³/min), stable pressure, suitable for medium and large-scale clean gas usage scenarios such as food and beverage filling and pharmaceutical production;

Oil-free scroll type: Small in size and low in noise (≤65dB), suitable for medium and small displacement scenarios such as laboratories and small medical equipment;

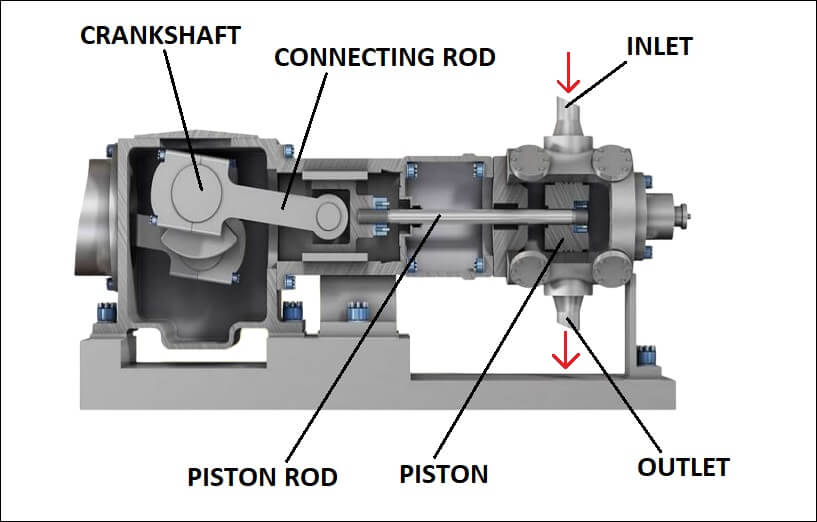

Oil-free reciprocating type (piston type) : High pressure (≤1.0MPa), low cost, suitable for small food packaging and local gas use in auto repair shops.

Oil-free centrifugal type: With an extremely large flow rate (> 100m³/min), it is suitable for centralized gas supply systems in the electronics semiconductor and large-scale chemical industries.

Is an oil-free compressor “maintenance-free”? What maintenance is needed on a daily basis?

Oil-free machines are not “maintenance-free”; instead, they have higher requirements for maintenance accuracy

Every 2000 hours: Replace the air filter element (to prevent dust from wearing down the coating);

Every 3000 hours: Check the rotor clearance (a laser micrometer is required; if the clearance exceeds 15 microns, it needs to be adjusted), and inspect the coating thickness (if the wear exceeds 30%, it needs to be recoated).

Water-lubricated models need to have their water quality tested monthly (deionized water should be replaced when the conductivity is greater than 5μS/cm) to prevent scale from blocking the waterways.

Conclusion

The cleanliness advantage of oil-free compressors and the cost advantage of oil-containing compressors essentially lie in the balance between “process requirements” and “input-output”. For industries such as food and medicine that come into direct contact with products, the Class 0 oil-free machine is an uncompromising bottom line. For scenarios such as mechanical processing that are not sensitive to oil pollution, an oil purifier combined with precise filtration is more cost-effective.

MINNUO suggests: First, clarify whether “air cleanliness affects product quality”, then calculate the full-cycle cost, and finally match the model. If you need further assessment, you can contact us to obtain the free “Industry Selection Manual” and let our professional team customize a solution for you.

Email

Email sales:+86 15366749631

sales:+86 15366749631