In high-risk scenarios of industrial production, the safe operation of compressors is directly related to the safety and efficiency of production. Take Europe as an example. According to statistics from the European Chemical Safety Association (ECHA), in 2024, there were 87 safety accidents caused by compressor equipment failures in the chemical and gas industries across the European Union, resulting in direct economic losses exceeding 350 million euros. On July 29, 2024, an explosion and fire broke out at the Ludwigshafen chemical plant of German chemical giant BASF due to equipment failure or operational error. Several key production facilities were severely damaged. The initial estimate of the losses caused by equipment maintenance, replacement and production standstill is as high as several million euros.

Safety standards are by no means optional “add-ves”, but rather “passes” for equipment to enter the market. In high-risk scenarios of the chemical industry, even an overpressure operation of 0.1MPa can lead to the leakage of corrosive media. In a CNG system, a 0.5mm sealing gap is sufficient to form an explosive gas cloud within 3 minutes under a pressure of 200bar. Ignoring these standards may result in a painful price for enterprises, such as production line shutdowns, complete equipment damage, or even casualties.

This article will use data to break down the core indicators of security standards, compare the applicable boundaries of different certification systems through scenario-based tables, and help buyers establish a three-dimensional assessment framework of “standard – risk – cost”, ensuring that every penny of the procurement budget is spent where security is most needed.

What are the safety standards for compressors used in the chemical, gas and hazardous materials industries?

Compressors used in the chemical, gas and hazardous materials industries, due to the high-risk nature of their application scenarios, must adhere to strict safety standards. These standards are the core norms for ensuring the safe operation of equipment in hazardous environments. The following are several typical safety standards for hazardous chemical compressors:

Safety standards for hydrogen compressors (H₂ compressors)

Hydrogen compressors are used in scenarios such as hydrogen refueling and chemical synthesis. The core safety requirements revolve around explosion-proofing, leakage prevention, and static electricity prevention, specifically including:

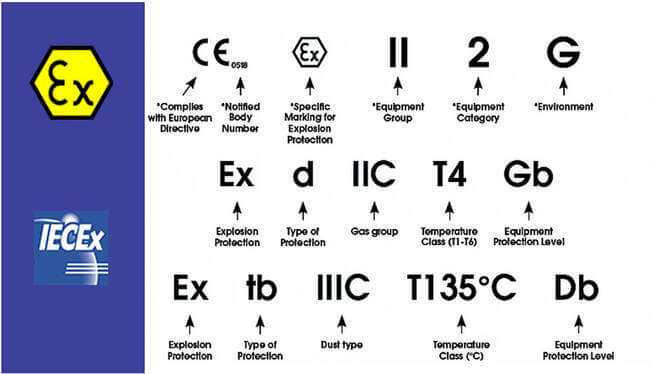

Explosion-proof performance: It is required to pass explosion-proof certifications such as ATEX, IECEx, GB 3836, etc. The explosion-proof grade is not lower than ATEX II 2G Ex d IIC T4 (adapted to the wide explosion limit characteristics of hydrogen). All electrical components must reach intrinsically safe design to avoid explosion caused by sparks.

Leakage prevention control: The static sealing leakage rate should be ≤0.005 standard cubic centimeters per second. Bellows mechanical seals or dry gas seals are adopted, combined with hydrogen-sensitive sensors for real-time monitoring to prevent hydrogen leakage from forming explosive gas clouds.

Anti-static requirements: The compression system must be equipped with a reliable grounding device (grounding resistance ≤4Ω). Metal parts in contact with hydrogen must eliminate sharp corners to prevent static electricity accumulation caused by high-speed gas flow friction.

Adaptation standards: It must comply with standards such as ISO 13468 (hydrogen compression System) and GB/T 34542 (Compressors for hydrogen refueling stations).

Safety standards for chlorine gas compressors (Cl₂compressors)

Chlorine gas compressors are used in chlor-alkali industries, water treatment and other scenarios. The core safety requirements focus on anti-corrosion, anti-leakage and toxic gas protection, specifically including:

Anti-corrosion requirements: Components in contact with the medium should be made of chlorine-resistant materials such as Hastelloy and titanium alloy. The annual corrosion rate of key components such as impellers and cylinders should not exceed 0.05mm. The casing should be treated with rubber lining or polytetrafluoroethylene spraying.

Leakage prevention control: Double-end face mechanical seals with leakage collection chambers are adopted, with a static leakage rate of ≤0.01 standard cubic centimeters per second. The system needs to be equipped with a chlorine gas detector (detection limit ≤0.5ppm) and emergency absorption devices (such as an alkali liquid spray system).

Material compatibility: The use of metals such as copper and nickel that react with dry chlorine gas is prohibited. The sealing parts should be made of perfluoroether rubber (FFKM) to avoid the generation of impurities or accelerated corrosion due to material reactions.

Adaptation standards: It must comply with standards such as GB 11984 (Safety Code for Chlorine Gas) and HG/T 20675 (Code for Design of Foundation of Chemical Machinery).

CNG Compressor Safety standards

CNG compressors are used in scenarios such as natural gas refueling stations and high-pressure gas storage. The core safety requirements revolve around high-pressure safety, explosion-proof control, and gas cleanliness, specifically including

High-pressure safety: It must withstand a working pressure of 200 to 250bar, pass strict pressure tests (such as a 250bar water pressure burst test, which is 1.5 times the actual working pressure), and be equipped with a reliable overpressure relief device. It needs to complete three automatic overpressure relief tests per hour to prevent high-pressure vessels from exploding.

Explosion-proof control: It must pass explosion-proof certification (such as ATEX, GB 3836, etc.), and use explosion-proof motors and explosion-proof control cabinets to prevent sparks generated by electrical system faults from igniting natural gas.

Gas cleanliness: The compressed natural gas must comply with the ISO 8573-1 standard (such as Class 1, solid particle content ≤1mg/m³) to prevent impurities from wearing equipment or blocking downstream pipelines and gas cylinders.

Adaptation standards: It must comply with standards such as GB/T 32226 (domestic) and ASME BPVC (American) to ensure stable operation in gas filling stations and gas storage facilities.

Main standard system

The core standards that compressors used in the chemical, gas and hazardous materials industries must follow include

Chinese standards such as GB 3836 (explosion-proof) and GB/T 32226 (CNG compressors) stipulate the basic safety requirements for the production and use of equipment in China.

International standard

ISO 8573-1 (Compressed Air Quality Grades, Specification for gas Cleanliness)

ATEX (European explosion-proof standard, suitable for potentially explosive environments);

ASME BPVC (American Society of Mechanical Engineers Standard, Specification for the Design of high-pressure Pressure Vessels)

IECEx (International Electrotechnical Commission Explosion-proof Certification System, a globally recognized explosion-proof standard).

Buyer’s pain point: What consequences will non-compliant devices bring

The standard system is complex and has significant regional differences, with a high compliance threshold

Different countries and regions have formulated differentiated standard systems based on their own industrial characteristics and security requirements, which poses a significant compliance challenge to foreign buyers.

Eu market The requirements for explosion-proof equipment stipulated in the ATEX Directive (2014/34/EU) must be strictly followed. For instance, in terms of explosion-proof grades, there are clear equipment category divisions for different hazardous areas (such as Zone 1 and Zone 2). If a CNG compressor is used in Zone 1, It is required to reach grade II 2G Ex d IIB T4 or above; At the same time, the quality of compressed air must comply with the ISO 8573-1 standard. Class 1 requires that the solid particle content be ≤1mg/m³ and the oil content be ≤0.01mg/m³. If any of these standards are not met, it will not be allowed to enter the EU market.

In the US market: ASME BPVC (Boiler and Pressure Vessel Code) has strict regulations on the design, manufacture and testing of high-pressure vessels for CNG compressors, such as passing the 300bar water pressure burst test (1.5 times the working pressure); UL certification (such as UL 1203) is a mandatory requirement for explosion-proof equipment. Equipment that has not obtained certification is not allowed to be used in hazardous locations. In addition, OSHA (Occupational Safety and Health Administration) will conduct strict reviews of the safety operation manuals, maintenance records, etc. of the equipment.

In the Middle East and Southeast Asia markets: Some countries, while adopting international standards, also attach localization requirements. If Saudi Arabia requires equipment to obtain SASO certification, in addition to the conventional safety performance, its test items will also take into account the impact of local high temperatures (outdoor temperatures in summer often exceed 50℃) on equipment operation, and it requires the compressor to operate continuously for 800 hours without failure in a 45℃ environment. Indonesia has special regulations on the corrosion resistance of imported compressors, which must be able to withstand the erosion of the equipment in the local high-humidity and high-salt environment.

If buyers lack a systematic understanding of the standards of the target market, they are very likely to encounter the problem of “certification misalignment”. For instance, compressors purchased for the European market that only meet the ASME standards of the United States may be detained by the EU customs due to failure to pass the ATEX certification. If the equipment purchased for the Middle East market does not take into account its adaptability to high-temperature environments, it may frequently experience overheating shutdowns during actual operation, leading to production disruptions.

The trade-off dilemma between price and long-term risk is prominent

The procurement cost of compliant equipment is significantly higher than that of non-compliant equipment, which has put many foreign buyers in a dilemma.

Cost structure differences: The material costs of compliant equipment are higher. For instance, if 316L stainless steel is used to make components in contact with the medium, the cost is over 50% higher than that of ordinary carbon steel. The cost of third-party certification is high. The cost of obtaining dual certification from ATEX and ASME usually exceeds 50,000 US dollars, and annual certification maintenance fees need to be paid. Therefore, the purchase price of compliant equipment is generally 40% to 60% higher than that of non-compliant equipment.

Short-term cost pressure: To alleviate the initial capital pressure, some small and medium-sized enterprises choose to purchase low-priced equipment from non-formal channels. These devices may reduce costs by cutting safety configurations (such as omitting dual mechanical seals and using low-grade explosion-proof motors), but the subsequent risks are huge. For instance, a buyer from Southeast Asia purchased a CNG compressor at a price 30% lower than that of the compliant equipment. After half a year of operation, a natural gas leak occurred due to a seal failure. Just the emergency repair and environmental testing cost 80,000 US dollars, far exceeding the initial cost savings.

Insufficient long-term risk awareness: Some buyers lack consideration of the full life cycle cost and ignore the possible fines and downtime losses caused by non-compliant equipment. In fact, from a 10-year usage cycle perspective, the total cost of compliant equipment (procurement + maintenance + risk cost) is usually over 40% lower than that of non-compliant equipment. However, many buyers are driven by short-term interests and find it difficult to make rational decisions.

The qualifications of suppliers are difficult to verify, and false advertising is hard to identify

The qualifications of suppliers in the international market vary greatly, and false advertising occurs from time to time, which increases the difficulty for buyers to select their products.

Certification fraud: Some suppliers deceive buyers by forging test reports, misusing certification marks and other means. For instance, compressors that claim to have passed ATEX certification have only undergone basic tests in reality and have not been subject to on-site audits by EU notified bodies such as TUV and SGS. Their explosion-proof performance simply fails to meet the standards. If the buyer fails to verify the authenticity of the certification, they may face legal risks after purchasing.

False performance labeling: Exaggerating key parameters, such as falsely labeling the corrosion resistance life of chemical compressors from the actual 5,000 hours to 10,000 hours, and falsely labeling the exhaust volume of CNG compressors from 300Nm³/h to 400Nm³/h. Out-of-town buyers find it difficult to conduct on-site inspections of the production process and can only make judgments based on written materials, which incurs extremely high verification costs. For instance, a certain European chemical enterprise, in order to verify the performance parameters of its suppliers, entrusted a third-party institution to conduct tests, and the testing fees alone amounted to 30,000 US dollars.

The cross-border after-sales response is lagging behind and the maintenance cost is high

Compressors used in the chemical, gas and hazardous materials industries are precision equipment. Their maintenance requires professional skills and original factory spare parts support. However, cross-border after-sales services often encounter many problems.

Long response time: Some suppliers have not established service centers overseas. When equipment malfunctions, technicians need to travel from China to the site, which may take 3 to 5 days one way. Adding the time for visa processing, the response period often reaches 7 to 14 days. According to industry standards, equipment malfunctions in hazardous locations should be responded to within 48 hours; otherwise, it may lead to safety accidents. For instance, the compressor of a CNG refueling station in the Middle East shut down due to a safety valve failure. It took the supplier 10 days to dispatch technicians from China. During this period, the refueling station was unable to operate, resulting in a direct loss of over 50,000 US dollars.

Difficulties in spare parts supply: The cross-border transportation cycle of original factory spare parts is long (usually 2 to 4 weeks), and it may be delayed due to customs inspection and other reasons. If key spare parts of the equipment (such as explosion-proof motors and seals) are damaged, it may lead to long-term shutdown of the equipment. The compressor purchased by an African buyer was shut down due to the damage of the magnetic drive component. It took one month to wait for the spare parts, resulting in a loss of the order value of 120,000 US dollars.

Insufficient technical support: The overseas technical teams of some suppliers have limited professional capabilities and are unable to solve complex faults. If a European buyer’s compressor experienced pressure fluctuation issues and local technicians failed to repair it multiple times, they eventually had to invite domestic experts to go, incuring an additional travel and service cost of 30,000 US dollars.

Core safety indicators: Parameters that must be confirmed when purchasing equipment

Explosion-proof grade comparison table

| Certification mark | Protective capacity | Applicable environment | Testing standard |

| ATEX Ex d IIB T4 | It can resist the explosion of Class IIB gases at temperatures ranging from -20 ℃ to 130℃ | Methane and propane environment | EN 13463-1:2019 |

| IECEx Ex ia IIC T6 | Intrinsically safe type, suitable for IIC gases such as hydrogen | Hydrogen energy storage tank | IEC 60079-25:2010 |

| GB Ex e II T3 | Increased safety type, allowing surface temperature ≤200℃ | Non-continuous explosive environment | GB 3836.2-2010 |

Technical parameters for sealing and leakage prevention

Double mechanical seals: Utilizing silicon carbide dynamic and static rings, they have a lifespan of ≥ 8,000 hours under a pressure of 150bar

Magnetic drive: Torque transmission efficiency ≥95%, zero shaft seal leakage (detection method complies with API 685 standard)

Leakage alarm system: Response time ≤0.5 seconds, capable of detecting flammable gas concentration as low as 0.1ppm

Pressure and flow matching formula

The selection of CNG compressors should meet the following requirements: Actual flow rate = number of gas guns ×15 cubic meters per hour ×1.2 (redundancy coefficient). For instance, a 6-gun gas filling station requires an exhaust volume of no less than 108 cubic meters per hour; otherwise, it will cause the gas filling machine to shut down frequently.

How to determine if a compressor meets safety standards?

Five key data items that a third-party test report must include:

The change in leakage rate after 1000 pressure cycle tests (should be ≤0.005 standard cubic centimeters per second)

Impact test results of explosion-proof enclosure (capable of withstanding 15J energy impact without cracking)

Temperature resistance test of motor windings (insulation resistance ≥100MΩ at 130℃)

The opening accuracy of the safety valve (within ±3% of the set value)

The efficiency curve of the filter element (filtration efficiency for 0.3μm particles ≥99.97%)

Scenario-based selection suggestion table

| Usage scenarios | Recommended compressor type | Core configuration parameters | Certification requirements | Average annual maintenance cost |

| Large-scale CNG master station | Three-stage reciprocating compressor | Displacement: 500Nm³/h, cylinder diameter: 160mm | Dual certification of GB and ASME | Approximately $4,000 – $15,000 |

| Fine Chemical Workshop | Diaphragm compressor | The maximum pressure is 40bar and the diaphragm life is ≥5000 hours | ATEX+ISO 15783 | Approximately $3,000 – $9,000 |

| Hydrogen energy demonstration station | Oil-free screw compressor | Oxygen content ≤5ppm, exhaust pressure 450bar | ISO 19880-3 | Approximately $12,000 – $35,000 |

The buyer’s cost-saving approach: Safety equipment = long-term savings

Centering on “Total Life cycle Cost (LCC)”, we reject the “low-price trap”

The international market has strict requirements for the safety and compliance of equipment. A reduction in short-term procurement costs often means a sharp increase in long-term risk costs. It is recommended to evaluate the total equipment expenditure through the LCC model, with a focus on the following dimensions:

The balance between purchase price and maintenance cost: The purchase price of compliant equipment may be 40% to 60% higher than that of non-compliant equipment, but the average annual maintenance cost is only one-third of that of non-compliant equipment (for example, the average annual maintenance cost of compliant CNG compressors in the EU market is about 8,000 euros, while that of non-compliant equipment can reach 25,000 euros due to frequent malfunctions). Based on a 10-year usage cycle, the LCC of compliant devices is actually lower (approximately 120,000 euros vs. 250,000 euros for non-compliant devices).

Quantitative assessment of downtime losses: According to EU industrial data, the average downtime loss for chemical enterprises due to compressor failures is 12,000 euros per hour, and for CNG refueling stations, it is approximately 5,000 euros per hour. Choosing equipment with intelligent early warning functions (such as vibration monitoring and abnormal temperature alarm) can reduce unplanned downtime by 80% and save over 100,000 euros in losses annually.

The advantage of residual value recycling: Compliant equipment, due to its compliance with international standards, has strong liquidity in the second-hand market. After 10 years of use, its residual value rate can reach 30% (for example, equipment originally valued at 100,000 euros can be recycled for 30,000 euros), while non-compliant equipment, as it cannot be resold, has almost no residual value.

Make use of regional certification mutual recognition and government subsidy policies

Many countries and regions have provided targeted subsidies, tax breaks or certification conveniences to promote the popularization of safety equipment. Making good use of these policies can directly reduce costs

Cross-regional certification mutual recognition saves repeated testing fees: The ATEX certification of the European Union and the UL certification of the United States are mutually recognized in some terms. Through the “one test, multiple certifications” model, 30% of the certification fees can be saved. For instance, equipment that has passed the IECEx international explosion-proof certification can be directly imported into countries such as Australia and Brazil that recognize this system without the need for repeated testing (the cost of a single certification can be saved by 20,000 to 30,000 euros).

Government subsidies and tax incentives

The Bipartisan Infrastructure Act of the United States for hydrogen energy projects stipulates that the purchase of oil-free compressors that meet the ISO 19880-3 standard can enjoy a 30% investment tax credit (up to a maximum credit of 500,000 US dollars).

The “Horizon Programme” of the European Union provides a purchase subsidy of up to 20% for CNG equipment that complies with ATEX and ISO 8553-1 Class 0 standards (applicable to emission reduction projects in the transportation sector);

The “National Industrial Development Programme” (NIDLP) of Saudi Arabia in the Middle East offers a 15% reduction in import tariffs for locally assembled compressors that have passed SASO certification.

Energy efficiency subsidy: Energy-saving compressors certified by the EU “Ecolabel” can enjoy electricity price discounts (such as the German industrial electricity price discount of 0.03 euros per kilowatt-hour). Calculated based on an annual electricity consumption of 10,000 kilowatt-hours, 300 euros can be saved each year, totaling 3,000 euros over 10 years.

Optimize procurement channels and cooperation models

Reduce procurement costs while ensuring compliance through supply chain integration and flexible cooperation models

Regional agency direct procurement reduces intermediate costs: By choosing the direct agent of the equipment manufacturer in the target market (for example, European buyers purchase Asian brand compressors through local agents in Germany), the price increase by 3-4 levels of middlemen can be reduced, and the purchase price can be lowered by 10% to 15%. At the same time, it ensures the after-sales response speed (such as on-site service within 48 hours).

Long-term framework agreements lock in prices: Sign a 3-5 year framework agreement with suppliers, stipulating that the purchase volume (such as 5 units per year) can be exchanged for a 5% to 8% price discount, and at the same time lock in the supply price of spare parts (to avoid cost fluctuations caused by rising raw material prices). For instance, a certain logistics group in Europe signed a three-year agreement with a compressor manufacturer to purchase 15 CNG devices, saving approximately 60,000 euros in total costs.

Leasing and trade-in model: For short-term projects (such as a temporary natural gas processing plant in the Middle East with a construction period of 2 years), equipment leasing (with a monthly rent of approximately 3% of the purchase price) can be chosen to avoid idleness and waste. Long-term users can participate in the “trade-in” program, where the residual value of the old equipment can be used to offset the purchase price of the new equipment (for example, a certain chemical enterprise in the United States used a 5-year-old machine to offset 20% of the purchase price of the new equipment).

How does MINNUO meet and exceed safety standards

MINNUO compressors have always adhered to the highest international safety standards as their benchmark. Relying on China’s well-established supply chain system – the cluster advantages from precision castings to core control systems, they have achieved efficient collaboration throughout the entire process of R&D, production, and certification. While fully meeting the compliance requirements of mainstream markets such as the European Union, the United States, and the Middle East, it can also provide global customers with solutions that are both safe and economical at highly competitive costs.

The precise adaptation of technical parameters to international standards

Explosion-proof grade It meets ATEX II 2G Ex db IIC T6 (EU standard) and UL 1203 Class I Div 1 (US standard), and can operate stably in extreme environments ranging from -40 ℃ to 85℃, fully covering high-risk gas scenarios of Class IIC such as natural gas, hydrogen, and methanol. It is two protection grades higher than the industry average explosion-proof grade.

Leakage control: The static leakage rate is as low as 0.003 standard cubic centimeters per second. It has passed the strict API 685 test and is 60% better than the international average (the industry average is approximately 0.0075 standard cubic centimeters per second). In the project of the North Sea oilfield in Norway, no medium leakage records have occurred during continuous operation for 12 months.

Intelligent system: It adopts an industrial Internet of Things architecture in compliance with ISO 13408-1, collecting pressure, temperature and vibration data every 50ms. The predictive maintenance accuracy rate reaches 92%, which is 15 percentage points higher than similar products in Europe. It can warn of potential faults 72 hours in advance.

Relying on the cost advantages of China’s supply chain in material procurement and precision manufacturing, MINNUO can transform these safety performances that exceed industry standards into cost-effectiveness that customers can perceive – under the premise of providing a full range of international certifications (ATEX+UL+IECEx, etc.) The equipment procurement cost is on average 15% to 20% lower than that of European and American brands, making compliance and safety no longer a high-price threshold.

Empirical performance in international projects

In a large-scale CNG refueling station cluster project in the Middle East, MINNUO compressors withstood the test of a 52℃ high temperature and high sand and dust environment, operating continuously for 730 days without failure. Compared with the local original brand used, they reduced the number of shutdowns by 18 times, saving the customer over 450,000 euros in downtime losses in total. Such reliability is precisely based on the dual support of “China’s supply chain efficiency + international standard compliance”, which not only ensures the long-term stability of the equipment but also reduces the initial investment of customers.

Build a global security ecosystem

MINNUO is well aware of the strict requirements of international customers for after-sales response. It has established three regional service centers in Germany, the United States, and the United Arab Emirates to achieve:

Technicians will be on site for response within 4 hours in the European Union, 8 hours in North America and 12 hours in the Middle East

Provide 3 years of free calibration service (in compliance with ASME BPVC calibration standards)

Original factory spare parts are stocked in global warehouses to ensure that key components are delivered within 48 hours

Safety standards have never been a “barrier” to international business, but rather the cornerstone of cooperation. MINNUO, leveraging its deep integration capabilities in the Chinese supply chain, combines “complete compliance certification” with “cost control” – it has established a solid safety defense line through 1,500 pressure cycle tests (ASME standards), triple explosion-proof certification, and zero leakage design, while enabling global customers to obtain the same or even better quality at a more favorable price. Truly achieve “safety without compromise and value maximization”.

Conclusion

In the selection of compressors for chemical, gas and hazardous materials applications, safety standards are an unassailable cornerstone. They are like the universal language of the global industrial safety system and the prerequisite for equipment to enter the international market and ensure stable production. Whether it is the ATEX Directive of the European Union, the ASME standard of the United States, or the SASO certification in the Middle East, behind each regulation lies the protection of life safety and the sustainable development of industries. Ignoring the selection of standards will eventually come at an incalculable cost.

If you are troubled by choosing compressors for chemical, gas and hazardous materials use, you might as well get the free selection and evaluation service provided by MINNUO. Our professional team will tailor the most suitable equipment selection plan for you based on your specific usage scenarios, process requirements, etc., allowing you to achieve the optimal configuration of the equipment while ensuring safety. Don’t let non-compliant equipment become a hidden danger to your enterprise’s development. Choose MINNUO, choose peace of mind and reliability, and build an impregnable defense line for your production safety.

Email

Email sales:+86 15366749631

sales:+86 15366749631