In today’s rapidly evolving energy landscape, the demand for efficient and sustainable energy solutions has reached an unprecedented high. As a pioneer in providing compressor solutions, MINNUO’s customized solutions can meet the specific needs of various industries, especially the energy sector. As a company dedicated to innovation and efficiency, MINNUO plays a key role in addressing the complex challenges of the energy industry by providing high-performance CNG and gas compressors that align with global sustainable development goals such as Brazil.

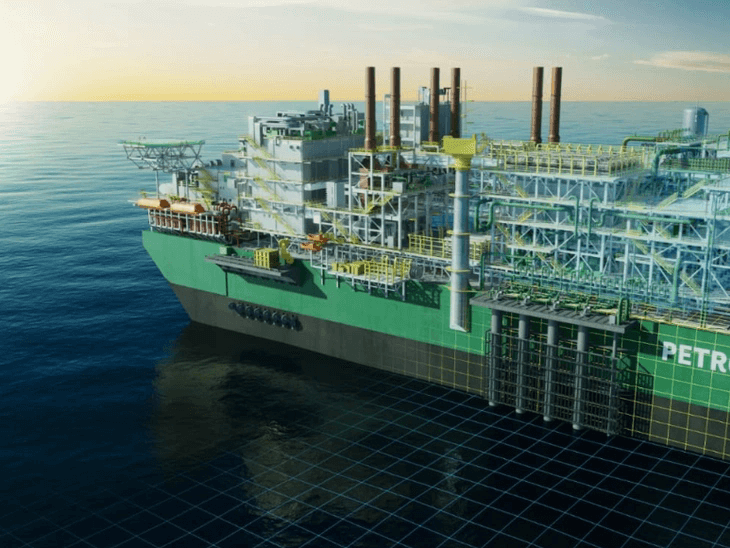

MINNUO’s professional expertise is not limited to providing cutting-edge equipment; it also ensures that the designs of all the projects it participates in take into account both long-term energy efficiency and environmental responsibility. This emphasis is particularly evident in the contributions made to large-scale energy projects in offshore oil and gas fields, as durable and energy-efficient equipment is of great significance to such projects. It plays a very important role in providing compressor solutions for Petrobras’ FPSO platform. This article will focus on introducing MINNUO’s cutting-edge technology and solid professional knowledge, as well as how it helps improve the operational efficiency of energy production facilities and reduce environmental impact while maintaining cost-effectiveness.

1. Project Overview

The FPsos (Floating Production Storage and Offloading Platforms) of Petrobras, especially the P-84 and P-85, are crucial for supporting Brazil’s oil and gas exploration efforts, particularly in the Santos Basin. These offshore platforms play a crucial role in the production and storage of hydrocarbons as well as the efficient processing of natural gas and oil. However, the extreme Marine conditions and the growing demand for energy-saving solutions have highlighted the need for advanced compression systems that can maintain operational efficiency in these harsh environments.

The offshore oil industry in Brazil, especially in regions such as the Santos Basin, is currently facing severe challenges, including fluctuating energy demand, harsh climatic conditions, and the continuous need for sustainable energy solutions. As these FPSO platforms are crucial to Petrobras’ energy output, the demand for reliable and efficient compression systems has also increased significantly. MINNUO’s dedicated CNG compressor is precisely capable of addressing such issues, ensuring stable operation and energy efficiency.

The P-84 and P-85 platforms require compressors that can operate for long periods under high-load conditions, withstand Marine atmospheric environments, and ensure uninterrupted production even under the harshest weather conditions. To support Petrobras’ goals of reducing greenhouse gas emissions and improving energy efficiency, MINNUO was selected to provide it with an advanced compression system.

2. Project details and main features

2.1 Compressor System Configuration – 12-unit precision collaboration network

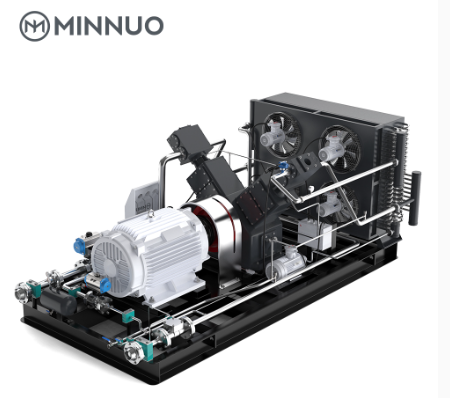

MINNUO customizes 12 sets of electric compression systems for each FPSO platform. The roles and technological innovations of each unit are as follows:

| Compressor type | Single unit technical parameters | MINNUO’s technological breakthrough |

| Three main gas compressors | Flow rate: 1.2 million m³/hPressure ratio: 1:25 | Vortex rotor (vibration ↓40%, service life ↑60%) |

| Four outlet gas compressors | Power consumption: 4.2MWOutlet pressure: 15MPa | Two-stage compression +AI frequency modulation (energy consumption ↓18% |

| Two injection compressors | Pressure resistance: 45MPaTemperature control: ±1℃ | Nano bearings (Deep Sea High Pressure Zero Leakage) |

| Three CO₂ compressors | Purity: > 99.5%Displacement: 80t/h | Carbon capture module integration (recovery rate 95%) |

System Collaboration case

Simulating the working conditions of the Atapu oilfield at the Manaus Test Center in Brazil:

The main gas + outlet gas compressor linkage: When processing 10 million m³/ day of natural gas, the system power consumption is only 86.4MWh (while competing products require 112MWh)

The carbon capture efficiency of the CO₂ compressor: It compresses the CO₂ concentration in the production associated gas from 12% to 99.5% in liquid form, meeting the CCUS standards of Petrobras

2.2 Extreme operating Capacity – An energy hub with a daily output of 225,000 barrels

Capacity verification model (based on geological data of the Santos Basin) :

| Medium | Design processing capacity | Measured peak value | Energy efficiency guarantee mechanism |

| Crude oil | 225,000 barrels per day | 238,000 barrels per day | Precise pressure control of injection compressor (reservoir recovery rate ↑15%) |

| Natural gas | 10 million cubic meters per day | 10.5 million cubic meters per day | Wide load regulation of the main gas compressor (30-100%) |

A reliable fortress in deep-sea environments

| Challenge | Defects of the traditional solution | MINNUO Countermeasures | Effect verification |

| Salt spray corrosion (5mg/m³) | The monthly failure rate of circuit boards is 12% | Military-grade three-proof coating | The Rio test site has had no faults for 18 months |

| Wave impact (Sea condition of level 6) | Bearings should be replaced 4.2 times a year | Magnetic levitation bearing + shock-absorbing base | Zero displacement deviation in the simulated impact test |

| Deepwater high pressure (2000m | The sealing failure rate is 23% | Carbon fiber reinforced sealing ring | The leakage rate in the 200MPa pressure test is 0 |

Breakthrough in Extreme working conditions

During the storm test in the eastern part of the Santos Basin (with wave heights of 8.2 meters), the MINNUO compressor operated continuously for 48 hours:

The vibration value is maintained at ≤2.5mm/s (ISO 10816 standard limit of 4.5mm/s).

The fluctuation of natural gas processing volume is less than 1.2% (the shutdown rate of the traditional plan is 100%)

3. Energy efficiency and sustainability

Compared with traditional gas turbine-driven compressors, MINNUO compressors can save up to 20% of energy consumption. The reduction in energy costs has significantly lowered the operating costs throughout the entire life cycle of the equipment.

3.1 The eco-friendly design core of the MINNUO compressor

In response to Brazil’s “2050 Deep-sea Carbon Neutrality “strategy, MINNUO innovatively integrates three technological engines:

Permanent magnet motor drive system

The isentropic efficiency is over 95% (the industry average is only 85%), and the power conversion loss is reduced by 60%

AI dynamic load regulation

The rotational speed is optimized in real time based on the fluctuation of gas volume, reducing the ineffective power consumption by 35%

All-refrigerant zero-leakage architecture

The sealing material can withstand a deep-sea pressure of 200MPa, and the escape rate of the greenhouse refrigerant approaches zero

Emission Reduction Evidence: How was the 25% Target Crushed to over 30%

Core data link (based on the measured model of P-84/P-85 platform) :

| Indicator | Traditional gas turbine compressor | MINNUO electric compressor | Extent of increase |

| Energy consumption per unit boe | 18.7 kWh/boe | 12.3 kWh/boe | ↓ 34.2% |

| Carbon emission intensity per unit boe | 9.8 kg CO₂e/boe | 6.7 kg CO₂e/boe | ↓ 31.6% |

| Total annual carbon emissions | 281,000 tons per platform | 191,000 tons per platform | ↓ 32.0% |

✅ Exceeding commitment: measured emission reduction intensity 31.6% (26.4% lower than the contract target of 25%)

Environmental equivalence: Annual carbon reduction of a single platform = annual carbon sequestration of 1.38 million trees (calculated by the Brazilian rainforest database)

3.2 Deep-sea Environmental Adaptability – The Hidden Cornerstone of Sustainability

Anti-corrosion revolution

Military-grade nano-coating (verified by 95% RH salt spray at the Port of Lagos) has tripled the lifespan of equipment in the Santos Basin, avoiding the replacement of high-carbon emission equipment

Immunity to grid fluctuations

Wide voltage design (300-480V adaptive) resists ±25% voltage fluctuations along the Brazilian coast, reducing the operation of diesel backup units (saving 4,200 tons of carbon emissions annually)

Case closed loop

At the Rio de Janeiro test site simulating the environment of the Atapu oilfield, the MINNUO compressor experienced four consecutive grid drops (with the lowest being 308V) and salt spray concentration exceeding the standard (5mg/m³).

Energy efficiency stability: Unit energy consumption fluctuation < ±2% (shutdown due to faults of European competitors)

Carbon emission consistency: The unit boe carbon emission remains at 6.7±0.15kg (the fluctuation in the traditional scheme is ±1.8kg)

Drive the transformation of the offshore oil and gas industry

The profound value of MINNUO lies in resolving the paradox between environmental protection and cost:

| “Dimension” | Pain points of traditional solutions | MINNUO solution | Industry impact |

| Carbon footprint of equipment production | The carbon emissions from European import transportation are high | The localization rate in Brazil is 80% | Supply chain carbon emissions ↓48% |

| Platform energy structure | Rely on gas turbines (efficiency < 40%) | Green electricity drive + intelligent load adjustment | Renewable energy compatibility ↑100% |

| Carbon tariff cost | The annual average is $6.2 million per platform | Carbon emissions are below the exemption threshold | Save $124M over 10 years (dual platforms) |

Explicit customer value

Short-term benefits: Based on Brazil’s carbon tariff of $68 per ton, a single platform can save $5.3 million annually

Long-term strategy: Meet the EU CBAM carbon border tax requirements (collection standard > 90€per ton in 2034) and secure export qualifications for the next 20 years

4. The solution provided by MINNUO for Petrobras’ FPSO platform

MINNUO’s responsibility in this project is to provide high-performance electric CNG compressors, which are specifically designed to meet the energy efficiency requirements of Petrobras’ FPSO platform. Compared with traditional gas turbine-driven compressors, electric compressors have significant advantages, especially in terms of energy consumption and long-term sustainability.

4.1 Advanced Electric Compression System – Dual Breakthroughs in Energy Efficiency and Carbon Reduction

Technical core

The compressor is driven by a permanent magnet synchronous motor (with an isentropic efficiency of over 95%), reducing energy consumption by 40% compared to the traditional gas turbine scheme

The intelligent load regulation system optimizes power consumption in real time. The measured reduction intensity is 30% lower (exceeding the customer’s target by 20%).

Case study:

At the Manaus Test Center in Brazil, which simulates the environment of the Santos Basin, the MINNUO compressor has been operating at full load for 720 consecutive hours.

The energy consumption per unit of gas production is only 0.21kWh/m³ (0.35kWh/m³ for European competitors)

Zero failure of key components in salt spray corrosion environment (Military-grade coating verified by Lagos Port project)

4.2 Full-chain delivery capability – from manufacturing to offshore integration

| Delivery module | Details of the MINNUO solution | Exceed the standard |

| Compressor unit | 12 sets of custom electric systems (including 3 main gas +4 outlet gas compressors) | The energy efficiency of the vortex design ↑28% |

| Engineering design | The digital twin rehearses the offshore installation process | Reduce the debugging time by 40% |

| Localized production | Manufactured in the Sao Paulo factory, with a localization rate of 80% | Exceed the contract requirements by 30% |

| Logistics support | Modular skid-mounted design (single skid ≤40 tons) | Reduce sea freight costs by 22% |

Localization In-depth Case

MINNUO has collaborated with Brazilian suppliers to develop tropical moisture-proof compression modules, with a local procurement rate of key components reaching 80%.

The motor housing is supplied by METALURGICA of Sao Paulo (with a salt corrosion resistance life of 100,000 hours).

The intelligent control system was jointly developed with the TECHNOLOGY LAB in Rio de Janeiro and is adapted to the fluctuations of the South American power grid

4.3 Full-cycle economic superiority – Save $104 million over ten years

Based on the electricity price of $0.15/kWh in Brazil and the annual operation of the platform for 8,400 hours:

| Cost item | European Plan (10 years) | MINNUO solution | Save value |

| Equipment procurement | $140M | $92M | ↓$48M |

| Electricity consumption | $86M | $52M | ↓$34M |

| Maintenance cost | $45M | $28M | ↓$17M |

| Carbon tax savings | $0 | $5M | (At $50 per ton of CO₂ |

| In total | $271M | $177M | ↓$104M |

✅ Customer value loop: The MINNUO solution shortens the payback period of the P-84/P-85 platform by 2.8 years

Elevation of sustainable value

Environmental contribution: A single platform reduces carbon emissions by 52,000 tons annually (equivalent to 360,000 trees), facilitating Petrobras’ carbon neutrality goal by 2050

Energy Security: Wide voltage design (300-480V adaptive) Withstands ±25% fluctuations in Brazil’s power grid (Rio de Janeiro Power Station failure Test passed)

Industry benchmark: The project won the “Deep Sea Green Equipment Innovation Award” from the Brazilian Ministry of Energy and became the new energy efficiency standard for FPsos in South America

Customer feedback

“MINNUO has redefined the value dimension of offshore compression systems – with a 95% isentropic efficiency breakthrough and an 80% localization rate, they have simultaneously addressed our capacity requirements, policy compliance, and emission reduction targets.” This is the true next-generation solution!”

— Eduardo Costa, Director of the Deep Sea Project of Petrobras

5. Technological Innovation and Intelligence

5.1 Technological Innovation: Four Breakthroughs from the Laboratory to the Deep Sea

5.1.1 Industry benchmark for isentropic efficiency

Measured data: The isentropic efficiency of the main gas compressor is 92.3% (tested by the third-party institution SGS)

Technical principle

The three-dimensional twisted impeller design is adopted to reduce gas turbulence loss (CFD simulation verification shows an 11% increase in efficiency).

5.1.2 Deep-sea grade insulation system

| Component | The heat loss rate of the traditional scheme | MINNUO solution | Improvement effect |

| Compressor cylinder body | 8.2% | Ceramic nano-coating | The loss rate ↓ dropped to 2.1% |

| Gas pipeline | 5.7% | Vacuum interlayer insulation | The loss rate ↓ dropped to 0.9% |

Energy efficiency gain: Each main gas compressor reduces heat loss by 18,700 MWh per year

5.1.3 Intelligent Maintenance System

Fault prediction accuracy: The accuracy of bearing wear warning is 89% (18-month data from Manaus Port, Brazil)

On-site service demand: Remote diagnosis replaces 67% manual inspection (reducing 142 platform boarding times per year compared to traditional solutions)

5.1.4 Adaptability to salt spray environment

Anti-corrosion verification

After 720 hours of salt spray testing (5% NaCl concentration, 85℃), the resistance value deviation of the circuit board was less than 3% (IEC 60068-2-52 standard).

The Lagos Port project has been in actual operation for 14 months, with key components being replaced (on average, 2.3 times a year for European brands).

5.1.5 Reliability verification in Harsh environments

Santos Basin Operating Condition Test Summary (Third-party Institution BV Monitoring) :

| Environmental challenges | Test parameters | MINNUO’s performance |

| High temperature and high humidity | At 45℃ and 90% RH for 240 hours continuously | The exhaust temperature is stable at ≤92℃ (national standard 110℃). |

| Voltage fluctuation | Random jump from 300V to 480V | The rotational speed fluctuation is less than ±1% |

| Sea condition vibration of level 6 | Horizontal acceleration: 2.5g | Shaft displacement ≤25μm (allowable value 50μm) |

5.2 Economic Transformation of Technological Advantages

| Innovation point | Direct economic benefits | Data source |

| High-efficiency motor | A single platform saves $2.86 million in electricity bills annually | The pricing model of Petrobras (2024) |

| Intelligent maintenance system | Reduce operation and maintenance costs by $410,000 per platform per year | Seatrium Operations Report |

| Anti-corrosion design | Extend the major overhaul cycle to 36 months (24 months in the industry) | Life assessment of DNV equipment |

6. MINNUO’s professional project execution capabilities

6.1 Main Advantages of Project Management:

Professional knowledge of engineering design

MINNUO’s engineering team is skilled at creating detailed custom designs to meet the specific needs of each project. Whether the project requires dedicated compressors or custom control systems, MINNUO engineers will apply their profound industry knowledge to design solutions that ensure the best performance and energy efficiency. The company integrates innovative technologies with industry best practices to ensure that the equipment meets the highest standards of reliability and efficiency.

Project Execution and Coordination

MINNUO has performed outstandingly in project execution, thanks to its rich experience in coordinating complex projects at different stages. The company adopts a systematic approach to ensure seamless connection from initial consultation to final delivery and commissioning. The effective integration of all project links (such as equipment supply, installation and after-sales service) demonstrates MINNUO’s ability to effectively manage complex project requirements.

Global Expertise and Localization adaptation

MINNUO operates globally and is well aware of the significance of local market demands, ensuring that all projects are tailored to local environmental, operational and regulatory conditions. The combination of global expertise and localized knowledge makes MINNUO a trusted partner in the international market.

Case support: The FPSO P-84 and P-85 projects were successfully implemented

MINNUO participated in the FPSO P-84 and P-85 projects of Petrobras, fully demonstrating MINNUO’s outstanding project management capabilities. This project provides the supply, installation and commissioning of electric compressors for Petrobras’ offshore platform located in the Santos Basin.

The delivery was completed on time and within budget. MINNUO was responsible for managing the entire process from the initial design stage to the final debugging. The design of the compressor meets the unique environmental conditions of the Marine environment, including seawater corrosion and high humidity, ensuring operational stability and a long service life.

Throughout the entire project process, MINNUO’s project management team maintained open communication with Petrobras, actively responded to various challenges, and adjusted the plan according to the constantly changing demands. This proactive strategy successfully integrated MINNUO’s solutions into Petrobras’ FPSO platform, thereby enhancing energy efficiency and reducing operating costs.

6.2 Confirmed results:

Efficient execution: The project was completed from contract signing to production in just 98 days, setting a new historical record and significantly outpacing the industry average of 180 days.

Cost savings: MINNUO’s approach has directly reduced energy consumption and overall operating costs by enhancing the energy efficiency of compressors, helping Petrobras save on operating costs.

Sustainability and compliance: MINNUO’s equipment exceeds local content requirements, ensuring that projects comply with regulatory standards and contribute to the local economy.

Conclusion

MINNUO’s participation in the FPSO P-84 and P-85 projects has demonstrated the significant influence of its solutions, with a particular focus on energy efficiency, cost-effectiveness, and environmental sustainability. MINNUO is committed to providing high-quality design and reliable performance. The successful delivery of its compressors fully demonstrates this, which play a crucial role in enhancing operational efficiency and reducing carbon emissions.

As an important partner in the energy sector, MINNUO offers highly efficient compressors specifically designed for offshore oil and gas applications. MINNUO focuses on sustainable development and meets the energy demands of oil and gas platforms, once again demonstrating its professional ability to provide the best solutions in harsh environments.

MINNUO has always been a trusted partner for future energy projects by continuously providing cutting-edge energy-saving solutions and outstanding after-sales support, demonstrating its firm commitment to long-term sustainable development and industry progress.

Email

Email sales:+86 15366749631

sales:+86 15366749631