Operating in harsh and high-altitude environments presents unique challenges for businesses relying on compressors. Factors such as reduced air density, extreme temperatures, and frequent dust storms can severely affect compressor performance, efficiency, and lifespan. These environmental elements are not just obstacles to consider—they directly impact the reliability and safety of your operations. Whether you’re in mining, oil and gas, or military applications, selecting the right compressor for your environment is crucial to ensuring continuous, optimal performance.

Choosing the right compressor for your specific environmental conditions is not just about avoiding breakdowns. It’s about achieving long-term operational success by reducing downtime, cutting maintenance costs, and lowering the risk of unexpected failures. Compressors designed for high-altitude or harsh environments are engineered to withstand extreme pressures, temperatures, and contaminants, making them essential for businesses that cannot afford interruptions or compromised performance.

In this article, we’ll break down the critical features that make a good high-altitude or harsh-environment compressor, from enhanced cooling systems to durability enhancements. We’ll guide you through the essential factors to consider when choosing equipment for these extreme conditions, so you can make an informed decision that supports your operational needs and boosts long-term efficiency. Keep reading to discover how to ensure your equipment performs reliably, no matter how challenging the environment.

1. Challenges in High-Altitude and Harsh-Environment Compressor Operation

High Altitude Challenges:

At high altitudes, the air density is significantly reduced, which directly affects compressor performance. The lower air density can lead to a diminished intake of air, causing the compressor to work harder to maintain the same performance levels. This challenge often results in the compressor struggling to achieve the required pressure or flow rate, which can eventually cause system failures or decreased efficiency.

Key Considerations:

Reduced pressure and lower oxygen levels lead to a decrease in compressor intake capacity.

Efficiency may suffer as the compressor struggles to maintain proper air intake.

Solution Tip:

Enhanced Intake Systems: When choosing compressors for high-altitude operations, it’s crucial to opt for models with enhanced intake systems that compensate for air density. Some compressors offer adjustable settings that allow them to adapt to environmental conditions such as varying atmospheric pressures.

Alternative Air Compressors: For extremely high altitudes (above 2,000 meters), consider selecting compressors that are specifically designed to operate at higher altitudes, ensuring performance consistency.

High-Temperature and Sandstorm Challenges:

High-Temperature Environments (Above 40°C):

In regions with extreme heat, especially above 40°C, compressors are subjected to thermal stress that can negatively impact performance. Overheated compressors often experience reduced cooling efficiency, leading to overheating and potential failure. The heat can also cause the lubricants to degrade faster, increasing maintenance requirements and operational downtime.

Dust and Sandstorms:

In arid and semi-arid regions, dust, sand, and other debris can clog intake filters, damage essential components, and compromise air quality. Not only does this lower compressor efficiency, but the increased wear and tear can result in frequent repairs and reduced equipment lifespan.

Solution Tip:

Dust-Resistant Features: To mitigate the effects of dust and sand, choose compressors equipped with specialized dust-resistant filters, enhanced heat-dissipation systems, and corrosion-resistant components. Consider models with sealed and weather-proof casings to protect against harsh external elements.

Cooling Systems for High Temps: Invest in compressors that feature advanced cooling technologies, such as integrated heat exchangers or air-to-air coolers, to ensure optimal cooling performance even in extreme temperatures. Models with built-in temperature regulation systems will help maintain efficiency and prevent overheating, even in the harshest climates.

2. Key Features to Look for in High-Altitude and Harsh-Environment Compressors

Optimized Air Intake Systems:

In challenging environments, air intake systems play a critical role in maintaining compressor performance. At high altitudes or in extreme heat, proper air intake design can significantly influence the efficiency and reliability of the compressor.

For High Altitude:

Enhanced Intake Systems: High-altitude compressors should be equipped with advanced intake systems to compensate for the reduced air density. Features such as turbochargers or high-efficiency blowers help maintain steady operation at lower atmospheric pressures.

Adjustable Settings: Compressors that come with adjustable intake systems can adapt to fluctuating altitude conditions, providing consistent performance even in areas with significant altitude variation.

Pro Tip: Select compressors with air intake systems that automatically adjust based on environmental pressure, ensuring optimal air flow and compressor efficiency.

For High-Temperature Environments:

Built-in Heat Dissipation: In extreme heat conditions (above 40°C), compressors should be designed with integrated heat exchangers, oil coolers, or temperature-regulated systems to manage the internal temperature efficiently.

Enhanced Motor Insulation: Compressors operating in high-temperature environments should come with higher motor insulation ratings (Class F or higher) to prevent overheating and ensure longevity under continuous high-temperature stress.

Solution Tip: Opt for compressors with robust cooling features like an enhanced cooling jacket or larger heat exchangers, which can help prevent thermal damage during long runs in hot climates.

For Dusty and Sandstorm-Prone Areas:

Dust-Proof Casings: In dusty or sand-prone areas, the compressor casing should be sealed to prevent debris from entering and damaging internal components.

Advanced Air Filtration Systems: High-efficiency air filters and washable filters can handle particulate matter, ensuring clean air enters the compressor. A good filter system is essential to prolong compressor life and maintain operational performance.

Waterproofing: Compressors for harsh environments should have components that are resistant to water ingress and humidity, ensuring the system remains functional even in wet or damp conditions.

Pro Tip: Choose compressors with easy-to-maintain filters and weatherproof casings that can withstand prolonged exposure to dust, humidity, and extreme weather conditions.

Durability and Longevity Features:

Given the demanding nature of high-altitude and harsh-environment operations, durability is a key factor when selecting a compressor. Compressors used in these conditions face more stress and wear, making it essential to choose models built for longevity.

Corrosion-Resistant Materials: Look for compressors made from materials resistant to corrosion, such as stainless steel or special coatings that protect the unit from environmental damage, especially in salty, humid, or acidic environments.

Durable Bearings and Seals: The compressor’s internal components should be built to handle extreme temperature fluctuations, moisture, and particulate matter. Bearings and seals that are specially designed to resist wear in harsh environments can extend the operational life of the compressor.

Pro Tip: Always select compressors that feature high-grade materials and seals designed specifically for your region’s climate, ensuring reliable performance and reducing maintenance costs in the long term.

Energy Efficiency and Low Maintenance:

Operating compressors in remote or harsh environments means dealing with increased operational costs. Selecting energy-efficient and low-maintenance compressors is crucial for reducing long-term costs.

Energy-Saving Features: Compressors with integrated energy-saving features, such as variable-speed drives (VSD) and energy-efficient motors, can reduce energy consumption by adapting the compressor’s output to the system’s demand.

Automatic Shutdown Systems: To minimize energy waste, look for compressors with automatic shutdown systems that turn off the compressor when not in use, helping save power in low-demand times.

Pro Tip: Choose hybrid or multi-stage compressors that provide enhanced adaptability to changing conditions, while also allowing for easy serviceability with minimal downtime during maintenance.

3. Case Study: How a Compressor Designed for High Altitudes Saved Costs and Downtime

Client Background:

A mining operation located in the Andes faced unique operational challenges due to its high-altitude setting, sitting at 3,500 meters above sea level. The reduced air density at such elevations and the extreme temperature fluctuations—often plunging below freezing—placed a heavy demand on their machinery. This high-altitude environment required compressors capable of maintaining reliable performance despite challenging atmospheric conditions.

Challenges:

The client initially used standard compressors that were not specifically designed for high-altitude use. These compressors frequently encountered operational issues:

Air Intake Problems: The compressors struggled to intake the correct volume of air due to the lower air density at 3,500 meters above sea level. As a result, the system failed to operate at full efficiency.

Overheating in Winter: During winter, the extreme cold temperatures caused frequent overheating issues as the compressors were not equipped with systems to regulate temperature effectively in sub-zero conditions.

Unplanned Downtime: The frequent operational failures and inability to maintain consistent performance led to significant unplanned downtime, which affected the mining operation’s overall productivity and incurred costly repairs and delays.

Solution:

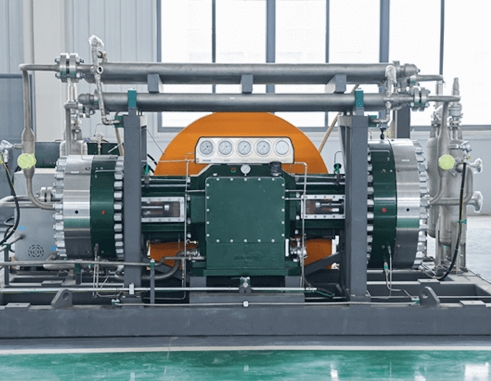

To solve these persistent issues, the client decided to switch to a customized MINNUO compressor designed specifically for high-altitude and harsh environments:

Optimized Air Intake System: The new compressor was equipped with a state-of-the-art intake system that compensated for the reduced air density, ensuring consistent and efficient operation even in high-altitude settings. This modification allowed the compressor to continue performing optimally, even with the lower air pressure.

Enhanced Cooling Technology: To combat overheating in extreme conditions, MINNUO introduced enhanced cooling mechanisms, including larger heat exchangers and better thermal management solutions, ensuring stable operation in both high-temperature and sub-zero conditions.

Low-Temperature Protection System: A low-temperature protection system was integrated to prevent damage during extreme winter temperatures. This added feature reduced wear and tear during colder months, further extending the compressor’s lifespan.

Regular Maintenance Checks: To ensure long-term reliability and minimal downtime, the installation of a regular maintenance protocol was introduced, involving routine checks and calibration specific to the high-altitude operational requirements.

Results:

After transitioning to the new MINNUO system, the mining operation experienced significant improvements:

Stable Operational Efficiency: The new compressor maintained stable performance even under sub-zero conditions, effectively eliminating previous temperature-related downtime. The optimized intake system and enhanced cooling technology ensured that the compressor continued running efficiently, even in challenging environmental conditions.

Reduced Maintenance Costs by 30%: The MINNUO compressor’s specialized features reduced the frequency of maintenance visits. By preventing the overheating and intake issues that plagued the original system, overall repair costs decreased, offering a 30% reduction in annual maintenance expenses.

Zero Unplanned Shutdowns: The installation of the customized system, including the air intake system and temperature regulation mechanisms, resulted in zero unplanned shutdowns during extreme weather conditions. This ensured that the mining operation could continue running smoothly, even during harsh seasonal changes.

4. What to Consider When Choosing a Compressor for Harsh Environments: A Buyer’s Guide

1. Altitude and Environmental Considerations:

What is the altitude and temperature range of your operational site?

Is the environment prone to dust, dirt, or humidity? If yes, choose filters that are specifically designed for dust control and maintenance ease.

2. Expected Load and Duty Cycle:

Are your compressors running 24/7? Choose heavy-duty, continuous-duty compressors.

Ensure compressors are rated for high-duty cycles without excessive overheating or component wear.

3. Durability and Material Quality:

Ensure the compressor components (cylinders, valves, bearings) are made from corrosion-resistant materials.

Opt for compressors that are weatherproof and able to operate in extreme temperatures and dust.

4. After-Sales Service and Maintenance:

Pro Tip: Choose compressors from reputable manufacturers (like MINNUO) that offer comprehensive after-sales support in harsh environments, ensuring long-term reliability and easy maintenance access.

Conclusion

Investing in a compressor specifically designed for high-altitude and harsh environments may come with a higher initial cost, but this investment pays off over time. These specialized compressors offer increased reliability and efficiency, significantly reducing maintenance needs and minimizing costly operational downtime. By selecting the right equipment, businesses can ensure consistent performance while saving on long-term maintenance and repair costs.

Choosing a reliable, purpose-built compressor ensures the stability and smooth operation of your entire system, especially in challenging environments. Whether it’s high altitudes, extreme temperatures, or dust-prone areas, the right compressor will guarantee that your operations run efficiently, avoiding the disruptions caused by equipment failure or environmental factors.

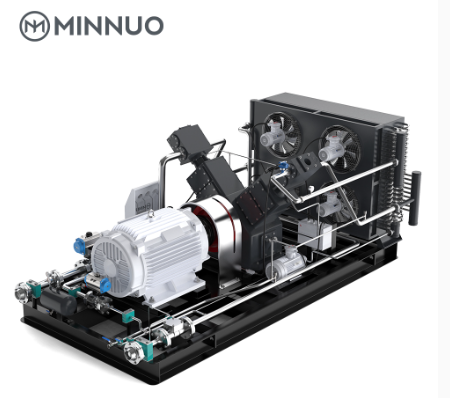

At MINNUO, we offer high-quality, durable compressors specifically designed to withstand the challenges of harsh environments and high-altitude operations. With our extensive experience in providing customized compressor solutions, we ensure that your operations are never compromised by the limitations of standard equipment. By working with MINNUO, you’re choosing a partner committed to enhancing the efficiency, reliability, and longevity of your operations in even the most extreme environments.

Email

Email sales:+86 15366749631

sales:+86 15366749631