In today’s precision-driven industries, compressed air quality is no longer a secondary concern—it is foundational to the success and safety of modern manufacturing processes. Whether in pharmaceuticals, electronics, or food production, the integrity of the final product increasingly depends on contaminant-free compressed air. This article explores the growing divide between oil-free and oil-lubricated air compressor systems and guides decision-makers toward smarter investments.

With clean production standards rising worldwide, particularly in Southeast Asia and Europe, the demand for oil-free air compressors has seen double-digit annual growth. Regulatory pressure, product quality expectations, and the rise of automation have made oil-free systems a preferred choice in cleanroom environments. Manufacturers are rethinking legacy systems and moving toward cleaner, safer alternatives.

This article provides a comparative analysis of oil-free and oil-lubricated systems, their performance, cost, and application impacts. It offers actionable suggestions for selection and implementation, especially for facilities looking to meet global clean standards. For readers evaluating new investments, a return-on-investment breakdown will help clarify long-term cost-efficiency. Read on to learn which system truly aligns with your business goals and product integrity demands.

1. Oil-Lubricated Compressors: Strengths and Limitations

Oil-lubricated air compressors have long been recognized as an efficient and durable choice in most industrial production environments. However, as cleanliness requirements have increased, especially in the pharmaceutical, food, and electronics industries, their limitations have come to light. A proper understanding of the advantages and limitations of oil lubricated machines is the key to making a reasonable equipment selection.

Working Mechanism: Lubrication Reduces Friction, Stabilizes and Enhances Lifespan

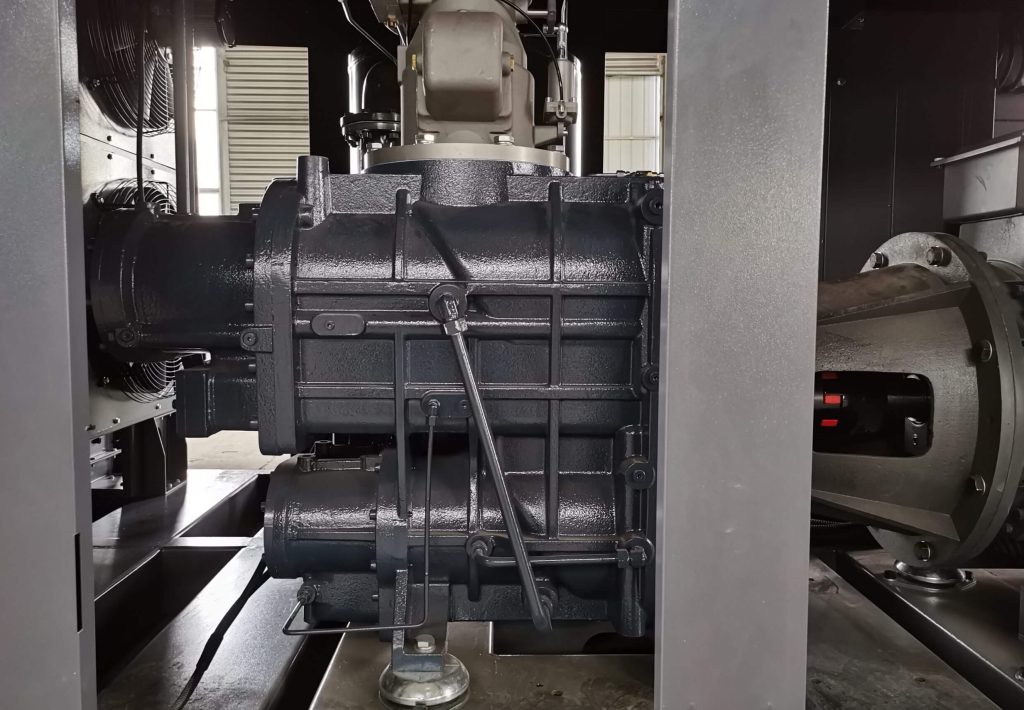

The basic working principle of oil lubricated compressors is to reduce friction between internal rotating parts by injecting lubricating oil, thereby reducing temperature rise and slowing down wear and tear. This not only improves mechanical efficiency, but also significantly extends service life. This durability is especially favored in industrial environments with high loads and long periods of continuous operation.

✅ Advantageous Scenario: High Load Efficiency and Lower Purchase Cost

In most standard industrial applications, oil lubricated air compressors show good price/performance ratios with their high compression efficiency and low initial purchase cost. For example, in steel, cement, machinery manufacturing and other areas where air cleanliness is not required, its operation is stable and economical. At the same time, the lubricating oil carries away some of the heat, improving thermal management during the compression process and indirectly reducing maintenance frequency.

Potential Risks: Residual oil contamination can lead to a chain of problems

Despite the reliable operation of the equipment itself, oil-lubricated compressors have a potential for residual oil and gas mixtures. Even after filtration through oil separators and cartridges, traces of oil and gas may still enter the gas delivery system, contaminating the end product or affecting the stability of downstream process equipment. For some clean sensitive industries, this risk is unacceptable.

Industry Restrictions: Use with caution or ban in high cleanliness industries

In industries such as medical gases, food packaging, and semiconductor manufacturing, the requirement for “zero pollution” of compressed air has become a rigid standard. In this type of scenario, even if the back-end configuration of high-efficiency filtration systems, but also can not completely eliminate the customer’s concerns about risk control. Some international standards (e.g. ISO 8573-1 Class 0) clearly recommend the use of oil-free compression systems in clean scenarios.

2. Oil-Free Compressors: How They Work and Why They Matter

In industries with high cleanliness requirements, such as food, pharmaceuticals, electronics, and medical gases, minute quantities of oil in compressed air can have serious consequences. Oil-free compression is just what these industries need.

A brief analysis of mainstream oil-free compression principles and technologies

Oil-free compressors usually use the following technologies to realize oil-free compression:

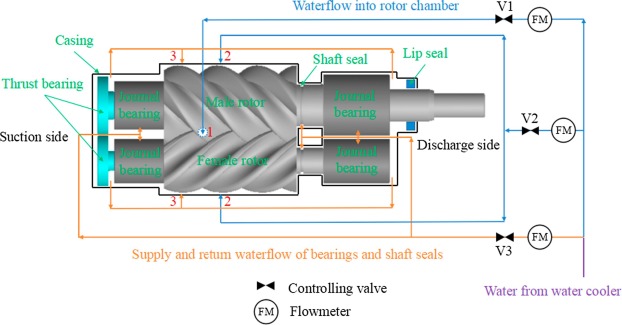

Oil-free screw compression (Dry Screw): contactless operation between two rotors driven by synchronous gears, avoiding oil lubrication;

Water-lubricated oil-free screw (water-cooled + water-lubricated): water instead of oil as the lubrication and cooling medium;

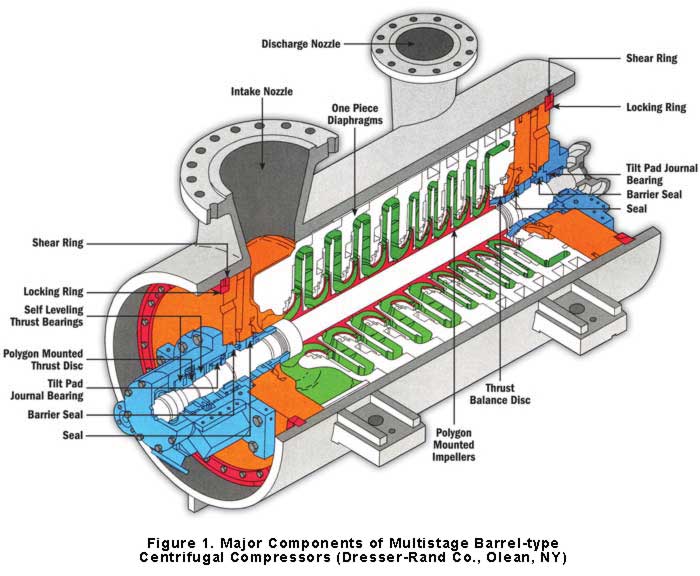

Oil-free centrifugal compressor: relies on the high-speed rotary impeller to Compression of air by means of a high-speed rotating impeller, suitable for high flow rates;

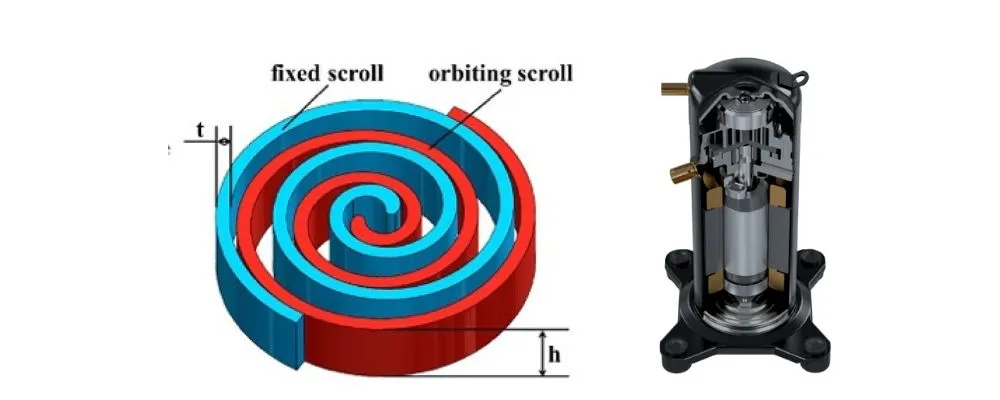

scroll oil-free compressors: compact, low vibration, suitable for laboratories or small installations.

Why are they important? A deeper understanding of the advantages and real value

1. Zero risk of contamination to support very high cleanliness requirements

Oil-free compressors directly avoid oil and gas contamination, eliminating the need for cumbersome back-end 3-stage and 5-stage filtration systems. In pharmaceutical (GMP), food (HACCP), electronics (clean room), etc., where air purity requirements are extremely high, compliance with ISO 8573-1 Class 0 is the basic threshold.

→ Practical problem solving:

A pharmaceutical factory still has dust contamination after using an oil machine, which was finally recognized as a filter element leakage leading to trace oil residue, and passed GMP certification after switching to an oil-free water lubrication system.

2. System simplification, reduce maintenance complexity and manpower

Oil-free means no need for oil-air separator, oleomargarine cartridge and other components, and no need to replace lubricating oil. The system structure is simpler, reducing maintenance workload and consumable costs by an average of 30%-50% per year.

→ Practical benefits:

Medium-sized food factories have reduced annual maintenance man-hours from 120 to 52 by replacing oil-free systems, while reducing the pressure on spare parts inventories.

3. Reduced Compliance Costs and Easier Safety Audits

The adoption of an oil-free system significantly reduces the number of product rejections, customer returns, or regulatory penalties caused by residual oil. Especially in the face of multiple regulations such as FDA, EU CE, ISO, etc., the oil-free system provides long-term safety guarantee for enterprises.

→ Example of actual scenario:

An exporter was rejected by Europe due to oil contamination of product batches, and then adopted Class 0 oil-free pneumatic system to avoid the repetition of the same incident.

4. Synergistic enhancement of energy saving and life cycle optimization

Modern oil-free compressors are often equipped with frequency converter control (VSD), heat recovery system, etc., to optimize energy use and extend the life of the whole machine, which is suitable for customers pursuing the optimal solution of long-term TCO (Total Cost of Ownership).

→ Actual energy-saving case:

An electronics factory equipped with a heat recovery module saves about 150,000 RMB in gas costs per year by using compression heat to preheat process water.

3. Application Scenarios: Where Oil-Free Is the Only Choice

In many industries, “oil-free” is not only a choice, but also a standard that cannot be compromised. The following four typical scenarios clearly show the status of oil-free compressed air as a “necessity”:

Food & Beverage Industry: Ensuring Clean Air, Guarding Product Safety

Usage Scenarios: Beverage Filling, Bakery Pneumatic Control, Packaging Film Blowing, Fermentation Air Supply, etc.

Problems and Pain Points: Residual oil contamination can easily lead to food spoilage, recall, and even brand damage to enterprises. Solution: Oil-free compressors can completely avoid lubricant contamination, meet HACCP, FDA and other standards, and do not require complex filtration in the back-end for direct contact with food.

Practical Benefits: Extend the service life of the equipment, reduce the risk of food safety accidents, and increase the rate of passing factory certification.

Medical and Pharmaceutical Industry: “Clean Bottom Line” in Critical Environments ”

Usage Scenario: Pneumatic valves in clean room, aseptic production delivery, injection tank filling, powder delivery

Problem: Drugs are susceptible to deterioration due to contamination by oil and particles in the air source, and the contamination will affect the efficacy of the drug and even the safety of the patients.

Solution: Oil-less pneumatic system is compatible with the GMP norms, and it can be used together with the clean piping system and the drying unit to form a complete clean air source system.

Practical benefit: Ensure the export of product compliance, reduce the risk of food safety, and improve the factory certification. Benefits: Ensure product compliance for export, reduce the cost of drug regulatory review and rectification, and help enterprises enter the European and American markets

Precision Electronics Manufacturing: Static electricity control and oil-free cleanliness at the same time

Scenarios: Semiconductor production, LCD panel manufacturing, chip placement, automated pneumatic actuator systems

Problems and pains: Oil may form a source of micro-pollution in the clean room, affecting the product qualification rate; and lubricating oil is a static-charged body, which is easy to cause the risk of ESD.

Solution: The oil-free system is naturally clean, does not cause secondary pollution, and meets the air source requirements of ISO Class

Practical Benefits: Reduce yield loss, avoid static breakdown events, and improve the yield of high-end electronic products.

Laboratory and High-end Scientific Research: Pure Air Source under the Requirements of Accuracy and Traceability

Usage Scenarios: Carrier gas for analytical instruments, clean bench air source, bioreactor air supply, precision weighing environment. Weighing environments

Problem: Oil or humidity changes in the air source can directly affect the results of experiments or accumulate errors over time

Solution: Oil-free air compressor with thermostatic drying system can provide stable, continuous air with very low dew point

Practical benefits: Improve the accuracy and consistency of experiments, meet the standards of GLP, ISO17025 and other laboratory accreditations

Beyond Clean: Why “Oil- Free” Is an Engineering Mandate Free” Is an Engineering Mandate

In the above industries, cleanliness is not only a goal, but also a rigid indicator of process control. Instead of using conventional oil-containing compressors and then purifying them through complex filtration, the choice of a virgin oil-free compression system is the solution that eliminates the risk of contamination at the source.

This choice is not just about “higher standards”, it is also about brand responsibility, productivity and global market compliance.

-1024x576.webp)

4. Total Cost of Ownership (TCO) Comparison

4.1 Purchase Cost vs. O&M Cost vs. Risk Cost

The initial purchase cost of an oil-free compressor is slightly higher than that of an oiled model, but this is more than offset by the savings in O&M costs and compliance risk. The long-term benefits are more clearly demonstrated through a Life Cycle Cost Assessment (LCC).

4.2 Filtration systems are replaced infrequently and the cost of contamination is close to zero

Oiled compression systems require complex filter packages to block oil mist, and once the filter element is saturated it will fail and contaminate downstream equipment, even affecting the end product. The oil-free system itself does not contain oil, the filtration system is simpler, the maintenance cycle is longer, and it is not easy to fail.

4.3 Longer service life, high system stability

High-quality oil-free screw compressors or scroll compressors, usually with more than 10 years of service life, and in long-term operation to maintain a stable gas output, not due to oil aging or contamination leading to performance degradation, reducing the frequency of replacement and downtime losses.

4.4 The return on investment cycle is more clear and controllable

Although the initial investment of the oil-free system is high, it does not require frequent replacement of oil, filter cartridge, pipe cleaning, and no need to deal with oil pollution waste gas and liquid, saving a lot of hidden expenses. It forms a stable ROI return curve in a 3-5 year cycle, which is especially suitable for industries that require high budget controllability.

✅ Actual savings pivot points:

Reduce the risk of product scrapping or recall due to pollution

Reduce the investment and operating costs of oil mist treatment facilities in the workshop

Enhance the environmental compliance score of the enterprise (green factory certification)

Reduce the expenditure of after-sales maintenance manpower and spare parts costs

5. Industry Standards and Certifications

International Standards and Certifications and Export Compliance: Extending the Value of Oil-Free Compressor Systems

Oil-free compressors not only offer advantages in terms of operational stability, but also in terms of compliance standards and international certifications, which are particularly suitable for companies wishing to enter the global market.

5.1 A brief overview of international certification requirements (e.g. ISO 8573-1, GMP, FDA, CE)

ISO 8573-1: Air cleanliness class standard with clear limits for particles, moisture and oil residues. Oil-free compressors are more likely to meet the standard and are suitable for the electronics, pharmaceutical and food industries.

GMP/FDA: Pharmaceutical companies are especially concerned about whether the process air meets the pharmaceutical production specifications. The use of oil-free systems makes it easier to pass the relevant auditing and record-keeping requirements.

CE certification: The passport to enter the EU market, some regions need to meet the EMC and Machinery Directives, oil-free models are more simple in design, and the compliance cost is lower.

5.2 How oil-free compressors help customers achieve compliance and export standards

Reduce the risk of oil contamination and avoid product recalls or customer complaints due to non-clean air sources.

The integrated design of the cleanroom and filling line makes it easier for customers to complete the overall certification of the system.

Provide a complete certification document package (material report, test records, factory inspection) to simplify the external audit process for customers.

5.3 Improve the passing rate of overall factory audit

When facing overseas customers’ factory inspection or third-party organizations’ audit, if the production equipment cannot provide clean gas records, it is very easy to be called back for rectification.

The use of oil-free compressors can effectively improve the overall “system cleanliness”, significantly improve the one-time pass rate, reduce the external audit rectification cycle and cost.

Practical suggestions: For export-oriented enterprises, it is recommended to consider the compatibility of certification at the early stage of selection, and prefer compression equipment vendors with global compliance experience, so as to avoid the waste of costs brought about by the later retroactive certification or system rectification.

6. Case Study: Clean Operation with Oil-Free Compressors

Below are two typical cases from Southeast Asia, Europe and the United States, showing how oil-free compressors can be used in actual clean processes and how they can help companies to solve the risk of contamination, improve the audit pass rate, and save operating costs.

Case 1: Thai Pharmaceutical Manufacturer Switches to Oil-free System to Meet GMP Certification

Customer Background:

A large-scale CDMO located in the suburbs of Bangkok, Thailand, mainly serves European and American customers and needs to pass WHO GMP and EU GMP certification. The original system was an oil-lubricated compressor with five-stage filtration, but the air quality was unstable and the certification was a risk.

Problems:

Compressed air sampling in pharmaceutical packaging area exceeded the oil content (>0.005 mg/m³), and was required to rectify the situation.

Frequent replacement of filters and activated carbon units, with annual replacement cost of more than 25,000 USD.

Internal audits repeatedly pointed out that “the system is too risky, with the risk of cross contamination”.

Solution:

Adoption of a MINNUO 37kW non-contact air compressor with a 5-stage filtration system. MINNUO 37kW oil-free, water-lubricated compression system + redundancy-level aftertreatment purification module

Establishment of a full process monitoring mechanism through real-time dew-point monitoring and Class 0 certified materials

Complete replacement of compressed air in high-risk areas with an oil-free source, equipped with a separate air line

Results and feedback:

Passed the 2024 EU customer pharmacovigilance review in one go, with no corrective actions

Maintenance savings of more than US$18,000 per year, with significant improvement in air quality consistency

Stable operation, noise reduction of more than 30%, zero oil contamination of the condensate and direct disposal of the emissions

Case 2: High-end French bakery avoids the risk of food contamination by switching to an oil-free unit

Customer Background:

A high-end frozen dough manufacturer in the south of France that caters to the supermarket chain, uses compressed air for direct contact with the food packaging and packaging materials. A batch oil mist contamination incident resulted in a large claim for damages.

Key Challenges:

Customer complaints about odors from bags, third-party testing confirmed oil in the air, and the entire batch was returned.

The French Food Safety Authority (FSSA) demanded that the company rectify its air system, and it faced a shutdown penalty.

It needed to replace the system with a high-cleanliness system without expanding the factory space.

Technical Implementation:

Installation of two MINNUO 75kW oil-free screw compressors with frequency control and food-grade chillers.

Modification of the existing piping network and upgrading to stainless steel polished piping to prevent oil deposits. Stainless steel polished piping to prevent oil deposits

Establishment of a daily inspection regime to ensure that the pressure dew point and oil content are well below the limits

Project results:

Stable air oil content of <0.001 mg/m³, passing all French and EU export standards

Savings of more than €40,000 per year in third-party testing costs and risk of accident claims

Significant reputational restoration of the brand, which has led to new orders from several international retailers orders from several international retailers.

Conclusion: Make the Right Choice for Your Process

Choosing between oil-lubricated and oil-free compressors goes far beyond technical specifications—it’s about compliance, safety, and long-term product integrity. Oil-lubricated compressors may pose a contamination risk, especially in industries like pharmaceuticals, food, and electronics, where even trace amounts of oil can result in costly product recalls or compliance failures.

When your process demands absolute cleanliness, low maintenance, and energy-efficient performance, an oil-free solution becomes not just an upgrade, but a necessity. By understanding your process requirements—such as final air purity class, usage patterns, and downstream application—companies can make informed decisions that align with both technical and strategic goals.

MINNUO supports global manufacturers in Southeast Asia, Europe, and the Americas with tailored oil-free air solutions. From initial selection to installation, our engineering team ensures that every compressor integrates seamlessly into your clean production line. Clean technology starts with clean air—choose MINNUO, and let your process breathe easier.

Email

Email sales:+86 15366749631

sales:+86 15366749631