In modern industrial systems, gas compressors play a vital role, not only as the core equipment for energy transmission and process execution, but also as a key link in the efficiency and safety of the entire production chain. Whether in the field of petrochemical, food processing, or gas recovery and storage, the selection of the right compressor directly determines the operating costs, equipment life and operational reliability.

However, in the face of a wide variety of complex parameters of the compressor market, many purchasers or technical personnel are often in the selection stage is caught in the wrong. Selection of the wrong equipment is not only hundreds of thousands or even millions of wasted investment in equipment, but also may lead to process gas source instability, high energy consumption, safety hazards occur frequently, and later maintenance and downtime losses is not to be ignored. Therefore, before purchasing, a comprehensive technical assessment and demand combing is a step that every buyer must pay attention to.

This article systematically sorts out the 10 key questions that should be paid attention to during the selection process, helping you to accurately identify the needs of your own working conditions, clarify the advantages and disadvantages of the configuration, and avoid blind purchasing. It will help you to accurately identify your needs, clarify the advantages and disadvantages of the configuration, and avoid blind purchase. Whether you are purchasing a gas compressor for the first time or seeking to upgrade or optimize an existing system, this guide will provide you with a reference value of technical judgment and selection framework.

1. What Type of Gas Will You Be Compressing?

The type of gas to be compressed is one of the central criteria in the selection of a compressor. Different gases have different physical and chemical properties, which have a direct impact on the safety of the equipment, sealing, material adaptability and compression mode.

✅ Clarify the hazardous characteristics of the gas

Before selecting the type, make sure that the gas belongs to the following categories:

Combustible gases (e.g. hydrogen, methane, propane): explosion-proof motors, anti-static seals are required, and the whole machine complies with the Ex certification standard

Poisonous gases (e.g. carbon monoxide, hydrogen sulphide): a fully enclosed structure with a leakage monitoring interface is required

Corrosive gases (e.g. chlorine, ammonia): the inner part of the unit needs to be made of 316L stainless steel or corrosion-resistant coatings

Easily Oxidizing gases (e.g. oxygen): oil-free compressor head is required to avoid the risk of explosion caused by the reaction between oil and oxygen

Project Case Reference:

In a hydrogen energy project in the Middle East, MINNUO configured an Ex d II BT4 certified explosion-proof compression system with a full set of Teflon seals and stainless steel high-pressure connectors to ensure the long-term safe operation of the system.

❓ Is oil-free, clean compression required?

Oil-free compression is required for the following industries or applications:

Medical oxygen (e.g. hospital oxygen supply systems)

Food-grade carbon dioxide (e.g. beverage aerating lines)

Fermentation reactions or electronic processes (e.g. semiconductor cleanrooms)

Aerospace, hydrogen production projects, and other scenarios that are extremely sensitive to contaminants

OIL-FREE COMPRESSOR TYPES AVAILABLE:

Oil-free screw compressors: suitable for medium to high flow rates, long run times

Oil-free piston compressors: suitable for high pressures, low flow rates

Membrane/diaphragm compressors: for high purity gases (e.g. H₂, He)

Recommendation:

If you are not sure about the cleanliness standards, it is advisable to inquire about whether you need to meet the ISO 8573-1 Class 0 oil-free class certification.

Different gases determine equipment configuration and safety regulations

| Gas Types | Seal material | Recommended Models | Special Requirements |

| Hydrogen, methane | Teflon/PTFE | Explosion-Proof Piston or Screw Compressors | Anti-static, explosion-proof zoning, leakage monitoring |

| Carbon dioxide (CO₂) | Stainless steel + acid-resistant coating | Two-Stage or Water-Cooled Models | Corrosion protection, drainage of condensate, temperature-controlled liquefaction prevention |

| Oxygen (O₂) | Oil-free + silicone-free seals | Oil-Free or Membrane Compressors | Prohibition of oil and grease contamination, degreasing of components required |

| Chlorine, ammonia | Hastelloy or titanium alloy | Rustproof Piston Compressors | Highly corrosive design, periodic seal replacement required |

2. What Are Your Required Pressure and Flow Rate?

Knowing the required operating pressure and flow rate is not just a matter of filling in technical parameters, but the most critical starting point in compressor selection. Errors in this part may cause abnormal system operation, excessive energy consumption, and even frequent equipment failure.

✅ Clarify the type of pressure: the difference between start-up pressure, maintenance pressure and peak pressure

Start-up pressure: the minimum pressure required when the system or equipment is turned on for the first time, and it is necessary to confirm the need for pre-charge function.

Maintenance Pressure: Stable pressure for continuous operation of the system, the most common operating condition of the compressor.

Peak Pressure: The maximum pressure value that occurs when the system is under extreme load, does the equipment need to be reserved for short-term overpressure capability?

Suggestion: If there are multiple gas consumption points or equipment, the maximum maintenance pressure + safety redundancy value should be used to set the output pressure range of the whole machine, to avoid equipment “pressure can not be”.

Analyzing flow fluctuations: peak vs. average flow

If there are obvious fluctuations in equipment air consumption (e.g., intermittent switching on), comprehensive consideration should be given to:

Peak flow rate: to meet the peak of air consumption without pressure drop;

Average flow rate: for energy-saving optimization.

Typical application comparison:

Continuous production (e.g. chemical/gas recovery): average flow rate is the main focus;

Intermittent operation (e.g. experimental equipment/packaging line): peak protection needs to be emphasized.

Solution Suggestion:

can be equipped with gas storage tanks or variable frequency control system to balance the flow fluctuation, not only to ensure the stability of gas supply, but also to avoid the waste caused by the “big horse pulling small car”.

Leave a margin, taking into account the future expansion needs

20~30% of the current capacity of redundant design, can avoid the future increase in equipment re-selection;

If there is a planned expansion or increase in the number of gas points, should be directly informed to the manufacturer, the engineers will consider in advance the host displacement, cooling system and the scalability of the control logic.

Common mistakes to avoid

| Frequently Asked Questions | Consequences |

| Provides only a vague “pressure/flow” parameter | lead to selection bias, the equipment has been in abnormal operation for a long time |

| Ignores ambient temperature/altitude, etc. | the actual exhaust capacity is greatly reduced |

| Does not take into account standby requirements and system parallelization | the system expansion after the supply is insufficient, or even need to completely reconfigure the pipeline |

3. What Is the Expected Duty Cycle and Operating Hours?

The operating cycle of the equipment not only determines the life of the compressor, but also directly affects the later energy consumption, maintenance frequency and operating efficiency. Clarify the running hours and load situation, is the watershed of the success of the selection.

⏱ Is it 24/7 operation? Or intermittent startup?

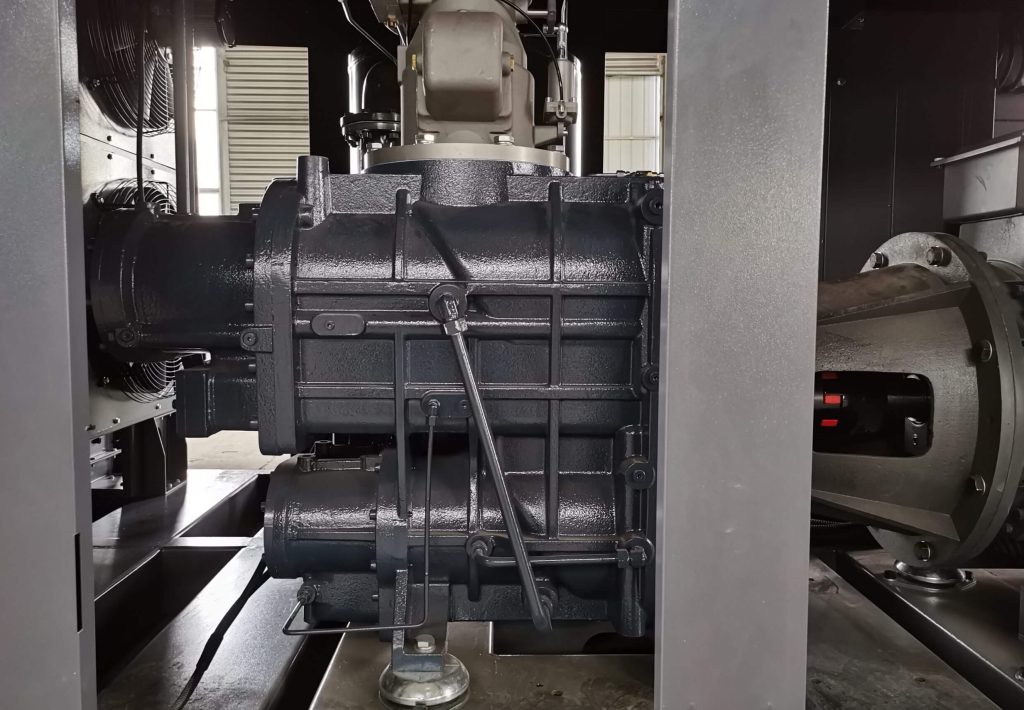

Continuous 24-hour operation: usually found in large production lines or central control systems, it is recommended to choose screw compressors with oil or water cooling systems to prevent overheating.

Intermittent working system: such as laboratories, packaging workshops, only 2~6 hours a day, you can choose a model with fast start-up response and strong energy-saving standby function.

Note:

Continuous operation is not equal to “stable operation”, if frequent start and stop or fluctuation is intense, it will accelerate the head loss.

Do I need waste heat recovery or thermal protection mechanism?

Under continuous operation, the equipment is under high temperature and high pressure for a long time. At this time, you need to focus on:

Does it have automatic cooling switching function?

Does the system support waste heat recovery for plant hot water or heating needs?

Is the system equipped with thermal protection automatic shutdown mechanism?

Application Scenario Example:

A pharmaceutical customer has 24-hour production, and the original system lacks thermal protection, resulting in frequent alarms on the air compressor. After replacing the system with a temperature control + waste heat export structure, the failure rate dropped by 80%, saving 12% of cooling power consumption.

The type of load determines the structure of the mainframe: full load or intermittent load?

100% load operation: choose the mainframe with constant power design to avoid frequent adjustment in high load area.

50~70% Partial Load Operation: It is recommended to use inverter control to save energy and prolong life.

Fluctuating load operation: If there is a difference in commuting time and the equipment does not use air evenly day and night, you should consider using dual machine switching operation or standby machine configuration.

⚠ Common Misconceptions and Suggestions for Avoidance

| Misconceptions | Potential Consequences |

| Thinking “the shorter the run time, the easier it is” | Frequent start/stop actually hurts the mainframe and increases the wear and tear of the control system |

| Using a normal constant speed compressor for highly fluctuating loads | Causes frequent loading/unloading of the system, which leads to serious power consumption and low system efficiency |

| Ignoring changes in operating conditions without mode adjustment | Serious overloading or idling in certain periods of time, which raises the operating costs and maintenance frequency |

4. What Are the Ambient and Inlet Air Conditions?

Evaluating the air quality and the natural environment at the site will help determine equipment selection, filter configuration, cooling system design and even the level of protection. The following are the key dimensions that users need to carefully consider before purchasing:

Are the intake air specifications compliant?

Intake air temperature: Is it in the hot zone above 45°C? If out of the standard range, consider adding a chiller or selecting a high-temperature unit.

Intake air humidity: Areas with high air humidity are prone to increased condensate, and need to be equipped with a high-efficiency drainage device or dryer.

Cleanliness requirements: If there is dust, oil mist, salt spray and other sources of pollution, it is recommended to install pre-treatment filters and precision filters.

Corrosive gases: If the incoming air contains SO₂, H₂S and other corrosive components, anticorrosive materials and surface coatings should be selected to strengthen protection.

Is the installation area environment complex?

Altitude: thin air in plateau area, need to recalibrate the motor load and cooling capacity to avoid insufficient compression ratio.

Climatic characteristics: desert, high humidity, coastal, extreme cold and other environments, all need customized solutions. For example, low-temperature starting device should be considered in extremely cold areas, and stainless steel should be selected in coastal areas.

Ventilation conditions: Does the indoor installation have forced ventilation? If the ventilation is poor, will cause abnormal temperature rise, it is recommended to design an independent air duct.

Space layout: Is there a narrow space, dense heat source, air out of the obstruction and other layout problems, affecting the efficiency of the machine heat exhaust?

Are there any special protection needs?

Does it need to be rain-proof, snow-proof, explosion-proof? Especially outdoor or dangerous working conditions, need to consider chassis sealing, explosion-proof motor, waterproof joints and other configurations.

Anti-corrosion treatment: Does the coating standard meet C3 or C4 level? Does it need anodized or epoxy protective coating?

Anti-sand and filtration structure: If located in the area with frequent wind and sand, a wear-resistant air intake system should be used and the filter element should be replaced regularly.

5. Do You Need Oil-Free or Lubricated Compression?

The choice between oil-lubricated and oil-free compressors in different industries is directly related to gas purity, system stability and maintenance costs. Before choosing, it is recommended to make a comprehensive evaluation from the following aspects:

Is Class 0 oil-free air required by industry specifications?

Industries such as medical, food, electronics and semiconductors require extremely high compressed air quality, and any trace of oil can lead to product obsolescence or contamination. For example, the pharmaceutical industry must meet the pollution-free requirements of GMP or FDA certification, and the use of Class 0 compressed air has become a necessity.

Do you have a complete air purification program?

In some cases, oil-free compressors are not mandatory, but a low-cost alternative can be achieved by installing a combination of high-efficiency oil filters + activated carbon adsorption + dryer. In this case, it is necessary to evaluate the frequency of cartridge replacement, pressure drop losses and long-term operating costs.

Is there a need for certification audits in clean areas or sterile environments?

If the compressed air is delivered to a clean room, filling plant or oxygen tank system, it is recommended to use an oil-free screw compressor with clean zone certification that supports 3Q verification documents, installation records, and operating curves, so that the customer can easily pass the audit and acceptance.

✅ Practical advice: For customers with unclear Class 0 requirements, we can provide a set of “oil-free + oiled + deep purification” dual program to facilitate comparison of ROI and operating costs.

6. What Power Supply and Voltage Are Available On-Site?

The power supply environment directly affects the selection of compressor models, operational stability and the need for transformers, soft start and other auxiliary equipment.

Confirmation of power supply specifications: 220V / 380V / 440V? 50Hz or 60Hz?

Most of the equipment default three-phase 380V/50Hz, if the customer’s factory for the North American standard of 440V/60Hz, you need to confirm that the compressor can be adapted to or through the frequency converter, to avoid burning or efficiency decline.

Is the power supply environment stable?

If the area is frequent power jumps, voltage fluctuations or cable aging, it is recommended to use an intelligent control system with over-voltage protection, delay restart, power failure memory and other protection modules, and optional UPS or utility bypass switching.

Does it support soft start or frequency conversion speed control?

High-power compressors that are not equipped with soft start/frequency conversion start may trigger peak current tripping, which is a higher risk especially in old plant circuits. The frequency control system enables on-demand loading, energy-saving operation and smooth starting.

Technical advice: Evaluate the “starting current vs. plant power supply margin” in advance to avoid the situation where the compressor cannot be used due to tripping after delivery.

7. Do You Require Any Specific Certifications or Standards?

When project delivery involves certification standards, compressor equipment not only needs to meet safety requirements, but also has a bearing on smooth customs clearance and acceptance.

Are there mandatory pressure vessel certifications in the target countries?

CE / PED for Europe, UL / ASME for North America, CSA for Canada, NR-13 for Brazil. When exporting, you need to check in advance whether the manufacturer has the relevant qualifications.

Are there any medical or pharmaceutical standards involved such as ISO13485 / GMP / SFDA?

If the compressed air is used in medical respiratory system, drug filling, injection dispensing, etc., the equipment should comply with the quality management system of medical equipment and provide validation documents.

Do you require nameplates and manuals in English and Chinese?

Export customers are often detained by customs or rejected by customers due to missing labels or manuals. We recommend choosing a supplier that can provide multi-language nameplates and operation manuals, certificates of origin, and third-party performance test reports.

Additional service suggestion: Choose the manufacturer with export experience, which can provide TUV, SGS, BV testing and foreign registration assistance to save customers’ time and cost in customs clearance and compliance audit.

8. Maintenance Resources: How Well Can You Maintain and Repair the Equipment?

When selecting a gas compressor, the ability to guarantee maintenance has a direct impact on the life and efficiency of the equipment. A practical assessment should include:

Is there a mechanism for localized O&M staff training?

Can the supplier provide Chinese/multi-language operation manuals and arrange remote or on-site training? Does it support quick start-up of operation by front-line workers?

Is the equipment modularized?

Modularization means that common faulty parts can be quickly disassembled and replaced, avoiding machine shutdown.

Does it support remote fault diagnosis and early warning function?

Equipment that supports remote diagnosis can detect problems in advance and reduce maintenance costs. For example, check the operation status or abnormal alarm through APP.

Is there a visual replacement guide for key parts?

Providing video tutorials or 3D model disassembly diagrams can help users complete daily maintenance independently and reduce dependence on the original manufacturer.

Is the after-sales maintenance transparent?

Clearly define the maintenance cycle, list of wearing parts and average replacement frequency, which helps users to estimate the annual maintenance cost and downtime.

9. Total Life Cycle Cost: Think Beyond Initial Price

Purchasing gas compression equipment should not only focus on the “price quote”, but also on the Life Cycle Cost (LCC) of the equipment. It is recommended to evaluate the following factors:

Energy efficiency:

For the same volume of gas, the electricity consumption of different compressors can vary by as much as 15-30%. Be sure to ask for data on gas consumption per unit (e.g. kWh/m³) and a description of the frequency conversion energy saving strategy.

Replacement cycle and cost of maintenance parts:

Some low-priced equipment may seem cheap at the beginning, but maintenance parts are expensive or replaced frequently, and the total cost in 3 years is higher than that of high-end equipment.

Availability of spare parts and maintenance resources:

Does it support the replacement of localized parts? Whether to establish overseas spare parts warehouse or agent system? Can directly affect the downtime and maintenance response speed.

System Optimization Capability:

high-quality brands often provide a complete set of system energy saving solutions, including front-end air compression, back-end air storage system and intelligent control platform linkage, to truly reduce operating costs.

10. Customization, Installation & Support: Does the Vendor Truly Understand Your Application?

High-quality suppliers not only sell equipment, but also provide customers with total solutions. Suggestions for inspection:

Is it possible to customize the solution according to the usage scenarios?

For example, is there any customized product for gas use under high temperature, low temperature, altitude, dust, corrosion and other working conditions? Is it possible to design different compression sections according to the actual gas components and gas volume requirements of users?

Is the installation and commissioning standardized and documented?

Do you provide access flow charts, installation layout diagrams, electrical interface diagrams, etc.? Does it provide remote assistance or door-to-door commissioning service for overseas projects?

Is the after-sales system mature?

Including response time commitment, overseas engineer stationing capacity, whether there is a local agent system, whether to support 5 years and above extended warranty service.

What is the logistics capacity of spare parts?

Does it support delivery within one week? Does it provide expedited delivery mechanism for urgent parts? Does it have global warehouses in cooperation with DHL/UPS?

Can users get continuous technical upgrades and equipment optimization suggestions?

Excellent brands usually provide customers with long-term energy efficiency optimization reports or suggestions for replacing more efficient parts based on big data analysis.

Conclusion

Behind every question, from flow requirements and pressure ranges to operating modes, cooling methods, oil lubrication or not, is the aim to ensure the long-term stability, safety and economy of the compression system. Only by asking these key points clearly at the selection stage can you avoid rework, excessive energy consumption or frequent maintenance in later use.

Buying a gas compressor is not a choice of individual equipment, but a systematic project involving matching of conditions, supporting systems, operating efficiency and after-sales support. We recommend that you talk to MINNUO, a manufacturer with many years of experience in the industry, to get a solution that really fits the needs of the site, and to avoid the selection mistake of “buying a compressor that doesn’t work, and using a compressor that always has problems”.

MINNUO provides one-on-one selection support, customized configuration suggestions, and can quickly generate technical solutions and quotations based on the basic parameters or working conditions you submit.

Email

Email sales:+86 15366749631

sales:+86 15366749631