Air Compressor For Laser Cutting Machine

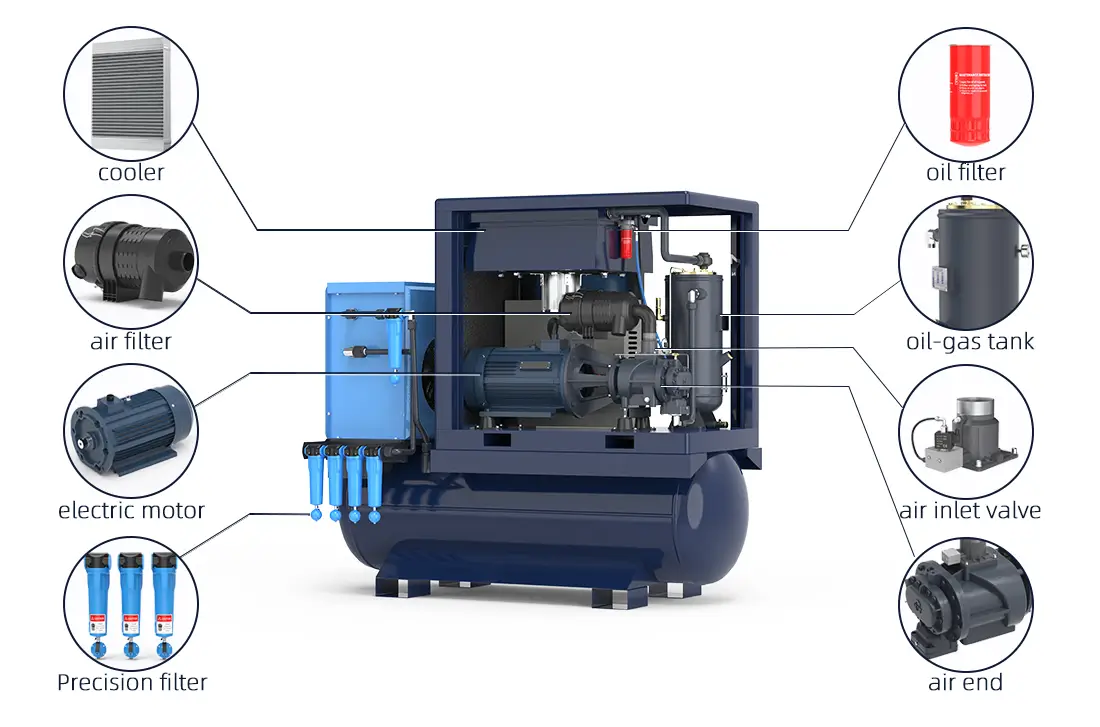

For laser cutting, the air consumption is small, usually choose 16 bar, 25kw, 22kw,37w air compressors. Due to the high requirements with the stability of air pressure and gas drying and cleanliness. Integration of screw air compressor, freeze dryer, precision filter, gas storage tank, and other components in one unit. Easy to install, simple to use, and flexible to move. Air quality is clearly optimized after the air has been integrated into the system.

- Working Power: 15~22kw,20~30hp

- Working Pressure: 16bar,232psig

- Treatment Capacity :45~65cfm,1.27~1.8m3/min

- Sound level: 58±2~65±2 dB(A)

Why air compressor for laser cutting?

The role of the screw air compressor for laser cutting machines is to compress a part of the air with high purity oxygen and high purity nitrogen to form the cutting gas to be supplied to the cutting head, a part of it is used as a power source to supply the cylinder for clamping the table and another part is used to purge the optical path system for dust removal. This is why an air compressor is essential for every laser cutting machine.

The advantage is that the cost of air cutting is very low, all it costs is the electricity consumption caused by the laser cutting screw air compressor to supply the air.

The quality of the compressed air has a direct impact on the quality of the metal laser cutting. The size and stability of the gas pressure affect the cutting results and require a dryer to remove moisture, a high-precision filter to remove oil and dust particles from the air, and an air tube to guarantee the volume of compressed air to enable the laser cutting to work continuously.

Therefore, integrated 4-in-1 air compressors are ideal for laser-cutting machines.

Advantages of 4-in-1 Screw Air Compressor For Laser Machine

The 16 bar screw air compressor for laser cutting is designed to meet the requirements of stable and clean air pressure for industrial laser cutting machines: it has the following benefits:

Highly integrated all-in-one machine: integrated air compressor, cold dryer storage tank, high-efficiency precision filter, all-in-one system, no need to install piping, with the characteristics of ready to install and use. Fewer components and connections, reducing the possibility of unit failure and leakage.

Superior performance: the integrated design provides you with an all-in-one air system and a complete compressed air solution designed to increase the value of use for the user.

Energy efficient: integrated duct connections. Reduced leakage and pressure drop, providing more compressed air and cost savings for the user. Energy-efficient drying system with a direct discharge of dry compressed air guarantees air quality for the user’s end use.

Practical and convenient: integrated design, designed for users to save space and installation costs, very quiet operation, can be positioned near the point of use.

THREE-IN-ONE AIR COMPRESSOR

| MODEL | MN-20A-PMIG-H | MN-30A-PMIG-H |

| MOTOR POWER(KW) | 15 | 22 |

| MOTOR TYPES | PERMANENT MAGNET MOTORS | PERMANENT MAGNET MOTORS |

| TREATMENT CAPACITY | 1.27 | 1.8 |

| PRESSURE(Mpa) | 1.6 | 1.6 |

| MOTOR SPEED(R/MIN) | 3000 | 3000 |

| DRIVE METHOD | DIRECT TYPE | DIRECT TYPE |

| AIR-COOLED DIMENSION (L*W*H) | 950*72*1000 | 1100*750*1100 |

| WEIGHT(KG) | 780 | 900 |

| NOISE DB(A) | 58±2 | 65±2 |

| OUTLET SIZE | G1" | G1" |

| COMPRESSED AIR OUTLET TEMPERATURE | AMBIENT TEMPERATURE+15℃ | AMBIENT TEMPERATURE+15℃ |

01. PM MOTOR

High efficiency design and SKF bearings ensure a long motor life.

IP54-protected, fully enclosed motor for trouble-free operation even under harsh working conditions.

Phase sequence protection as standard to prevent reverse rotation.

02. Air Tank

Large-capacity gas storage tank to ensure smooth gas pressure

Scientific calculation of the safe pressure, use more assured

Higher than standard safety requirements, operating pressure 1.68 MPA, test pressure 2.2 MPa

03. Mann Oil Filter

Automatic drain to reduce the load on the chiller. Pressure dew point 2-8℃, oil content not more than 0.001ppm, particle filtration accuracy 0.01μm

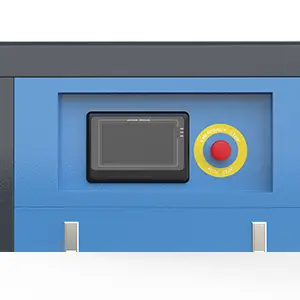

04. Micromputer PLC Control

Display air compressor operating status, fault alarm, parameter setting, temperature and pressure, total operating time and loading operating time, loading/unloading/full load display, emergency shutdown, operation mode, etc. record at least 30 historical alarm information, exhaust pressure,temperature and other historical information. Automatically load and unload, realize unmanned operation.

05.Cooling System

Design of large heat exchange are, can effectively avoid high temperature and adapt to bad working condition to ensure longer lifes.

06. High efficiency refrigerated dryer

Adopt high quality environmental protection refrigerant With electronic timing drain solenoid valve Pressure dew point as low as 2~8℃ Excellent water removal structure, strong cooling effect Ensure the compressor air is dry

Manufacturing & Test

We design and manufacture high-quality, low-price air compressors, and gas compressors, all products are designed and manufactured in strict accordance with standards, with an advanced digital inspection line, each tool test data verification, and advanced testing and verification procedures to ensure the quality of each equipment delivery.

Why Choose Us?

- Reliable quality assurance.

The 22KW 16kg laser cutting air compressor has optimized internal piping, reducing the energy loss caused by excess piping. Making the layout more reasonable and the product more beautiful, with fewer interfaces and less pressure difference, significantly preventing air and oil leakage and improving product quality. 10-year warranty

- More energy saving

The cooling fan adopts frequency conversion control, which can save more than 3% of energy consumption while reducing noise;

permanent magnet IPM motor, with eight high-speed motors, energy-saving efficiency is 10% higher than asynchronous motor; it can save 50% of electricity bill annually.

- Convenient operation

The integrated control system, one key to control the start and stop of the screw machine and cold dryer, makes it a more convenient operation.

- Lower noise and remote monitoring are possible.

The noise is only 63-75dB(A) and can control the machine status in time through the wireless network connection.

Send Your Inquiry Now!

We will arrange a free system solution design with your dedicated engineer to customise an energy efficient air compression solution for you.

No spam, notifications only about new products, updates. new instant price.

Email

Email sales:+86 15366749631

sales:+86 15366749631